HYDROLOGICAL SERVICES PTY LTD

_______________________________________________________________________________________

Gas Purge Operational Characteristics

In the foregoing, the discussion has been limited to static head conditions, whereas in practice,

the levels in stream are constantly fluctuating.

“Rising” Situations

It is the “rising” or “increasing head” situation that is critical for the correct operation system.

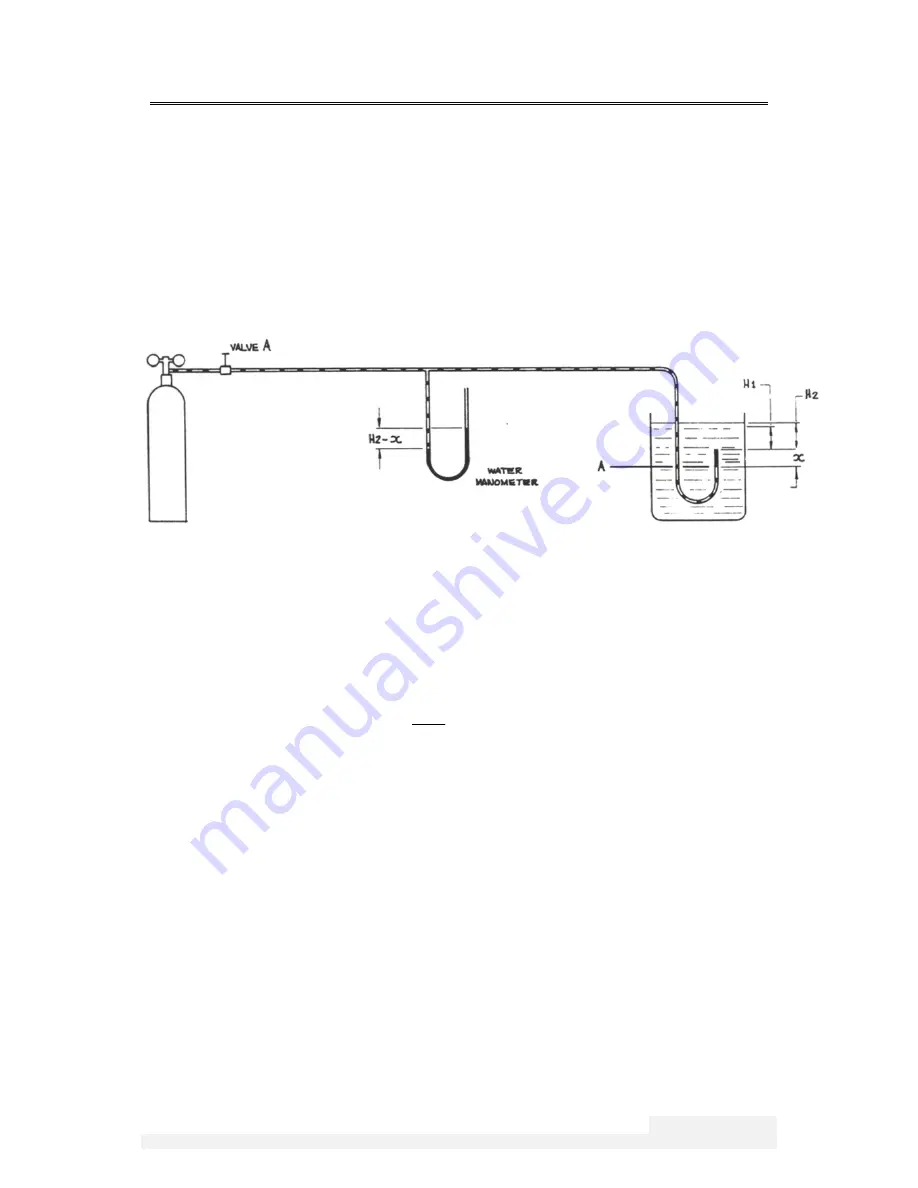

Consider a situation where the gas supply is cut off and the level rises- refer Fig.5.

Fig.5 - With gas supply cut off. Head increased from H1 to H2, gas is forced

down the tube by an amount X.

In this situation, it can be seen that whilst the system pressure has increased, it is not equal to

the new head H2, but rather H2-x. This condition will remain as long as the gas is shut off. In

other words, we now have a “closed” system, which respond to changes in accordance with

universal gas law-

a constant

PV

T

i

i

i

To revert back to the open system, we must restore gas supply, which will eventually build up

pressure in the system, until the gas escape from the orifice and the system pressure again

becomes the precise head measurement.

The time taken for the pressure system to respond to a given head pressure is commonly referred

to as “follow rate”. The normal procedure is to establish the maximum rate of rise to be

measured and adjust the gas flow so that there is no significant lag in the pressure system.

However, in order to conserve the gas supply, the flow rate (bubble rate) is set to the aluminium

that will meet these conditions.

Gas Purge Compressor

Issue 7:

16/12/03

© Copyright

HS55 110-017