2 | Safety

HYDAC FILTER SYSTEMS GMBH

18 / 60

MoWa CMP43x0-5 4191543c en-us print

Environmentally tip

Open ports

Oil leaking out from open ports

u

Soak up the leaking oil with an absorbent cloth and

dispose of it in an environmentally friendly way.

Life phase - Transport / Storage

The following risks could arise during the commissioning /

operation life phase:

Environmentally tip

Open ports

Oil leaking out from open ports

u

Soak up the leaking oil with an absorbent cloth and

dispose of it in an environmentally friendly way.

Life phase - Commissioning / Operation

The following risks could arise during the commissioning /

operation life phase:

CAUTION

Hot surfaces between electric motor and pump

Risk of burns

u

Allow the magnetic coupling to cool down.

Life phase - Maintenance / Troubleshooting

The following dangers could arise during the life phase of

maintenance / troubleshooting:

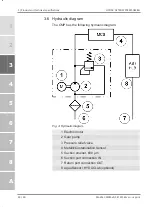

1

2

3

4

5

6

7

8

A

Содержание CMP 43x0-5 Series

Страница 60: ...www hydac com ...