REFRIGERANT

The correct type of refrigerant will be stamped

on each merchandiser’s serial plate. The case

refrigeration piping is pressurized, leak tested

and factory sealed. Before making refrigeration

hookups, depress universal line valve to ensure

that coils have maintained pressure during

shipment.

REFRIGERANT PIPING

Connection Location

The refrigerant line outlets are located under the

fixture towards the center (refer plan view ).

Insulate suction lines to prevent condensation

drippage on the floor.

Line Sizing

Refrigerant lines should be sized as shown on

the refrigeration legend that is furnished for the

store or according to ASHRAE guidelines.

Refer to data sheet included with this manual for

specific information on the case you are installing.

Oil Traps

P-traps (oil traps) must be installed at the base of

all suction line vertical risers.

Pressure Drop

Pressure drop can rob the system of capacity. To

keep the pressure drop to a minimum, keep the

refrigerant line run as short as possible using a

minimum number of elbows. Where elbows are

required,

USE LONG RADIUS ELBOWS ONLY

.

INSULATION

The suction and liquid lines should be clamped

or taped together and insulated for a minimum of

30 feet from the merchandiser. Additional insula-

tion for the balance of the liquid and suction lines

is recommended wherever condensation drippage

is objectionable or lines are exposed to ambient

conditions.

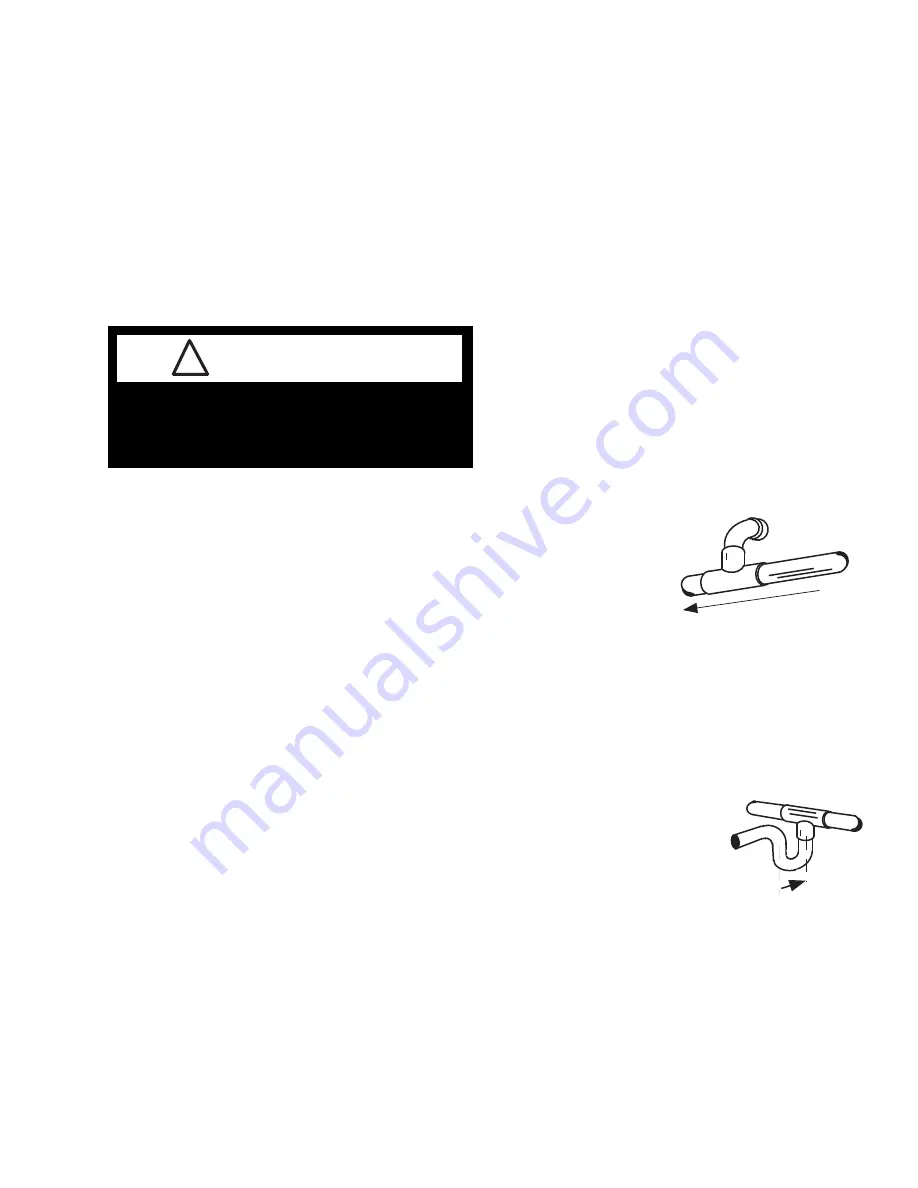

SUCTION LINE

• Pitch in direction of flow.

• May be reduced by one size at one third of case

run load and again after the second third. Do

not reduce below the case suction line size.

• Case suction lines

should enter at the

top of the branch

line.

LIQUID LINE

• May be reduced by one size after one half the

case run load. Do not reduce below the case

liquid line connection size.

• Take-offs to case liquid lines should exit the

bottom of the

branch liquid

line. Provide an

expansion loop

for each evapo-

rator take-off.

(Minimum 3 in.

(76 mm) loop.)

REFRIGERATION / ELECTRICAL

Refrigeration lines are under pressure and

should be depressurized before attempting to

make any connections.

WARNING

!

Island & Multi-deck Island

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

P/N 0446551_A

2-1

Suction Line Return

Minimum Loop

3-in. (76 mm)

Liquid Line Take Off