28

CUTTING UNIT – Cut-n-Break

18

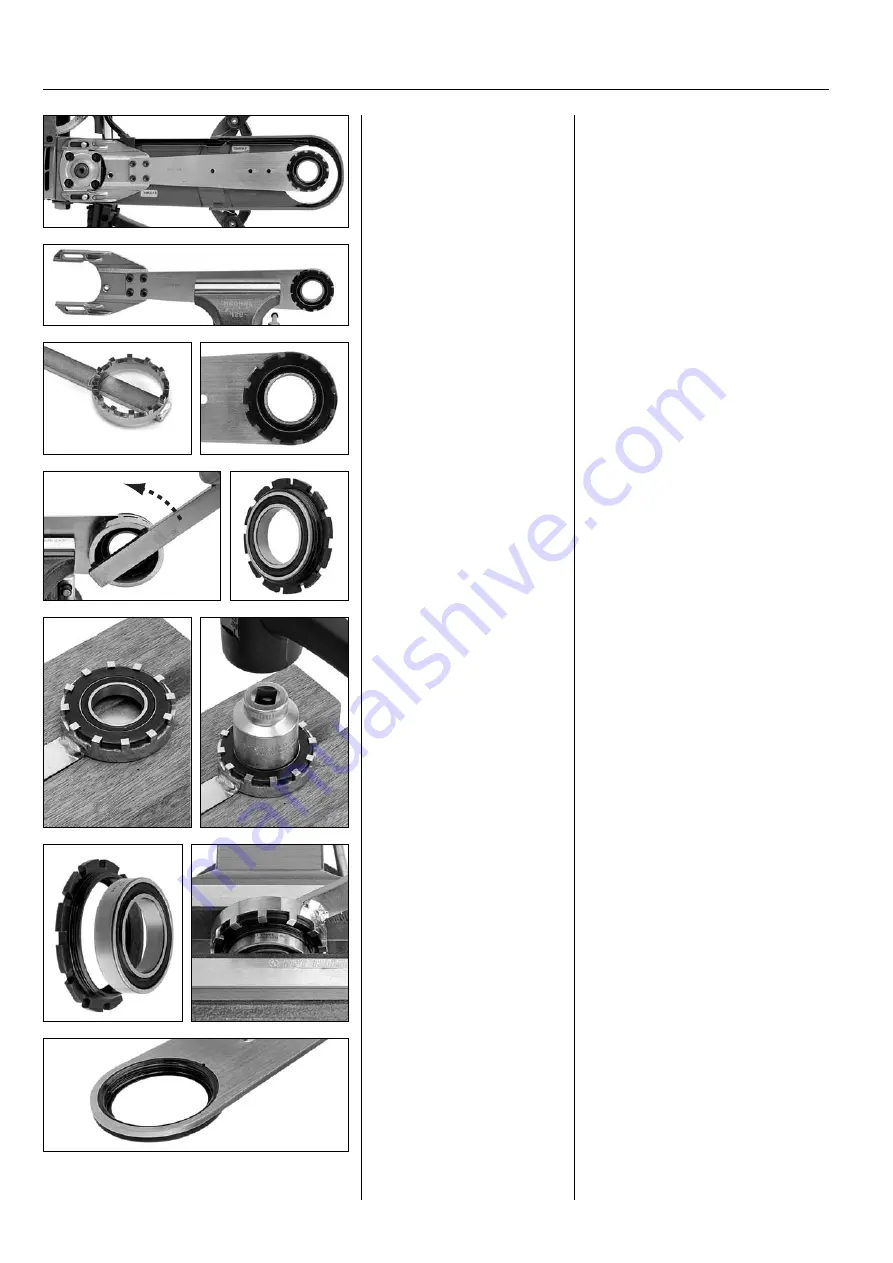

Fit the bearing

The bearing is best fitted by pressing.

Apply press force to the bearing's outer

ring.

Alternatively you can fit the bearing

using a vice as shown in the illustration.

Place the bearing holder in the special

tool to give the bearing holder good

support all around.

Fit the bearing

The bearing is best fitted by

pressing.

Alternatively you can fit the

bearing using a vice. Place the

bearing holder in the special

tool.

Tools

The special tool 502 53 15-01 is needed

for removal which is used to remove and

fit the threaded bearing holder.

Attach the cutting arm in a vice.

Attach the cutting arm.

Remove the bearing holder

Remove the bearing holder using tool

502 53 15-01. The bearing holder has a

fine thread.

Remove the bearing

Also use the special tool to press the bea-

ring out of the holder. Support the tool

ring with a pair of wood blocks as shown

in the illustration. Press or knock out the

bearing using a suitable socket.

Tools

The special tool 502 53 15-01 is

needed for removal.

Bearing replacement

The cutting arm, where the bearing is

fitted, is now accessible when the belt

guards are removed. See the “Belt replace-

ment” chapter where this work is

described.

Bearing replacement

Remove the belt guards.

Remove the bearing holder

Remove the bearing holder

using tool 502 53 15-01.

Remove the fixed bearing

holder

The bearing holder in the cutting

arm is positioned with a force

fit.

The following method for

removal works:

Remove the bearing

Support the tool ring as shown

in the illustration. Press or

knock out the bearing using a

suitable socket.

502 53 15-01

Remove the fixed bearing holder

The bearing holder in the cutting arm is

positioned with a force fit. It is difficult

to remove as there is no chance of achie-

ving a good counter hold

The following method works: