17

SERVICE AND ADJUSTMENTS

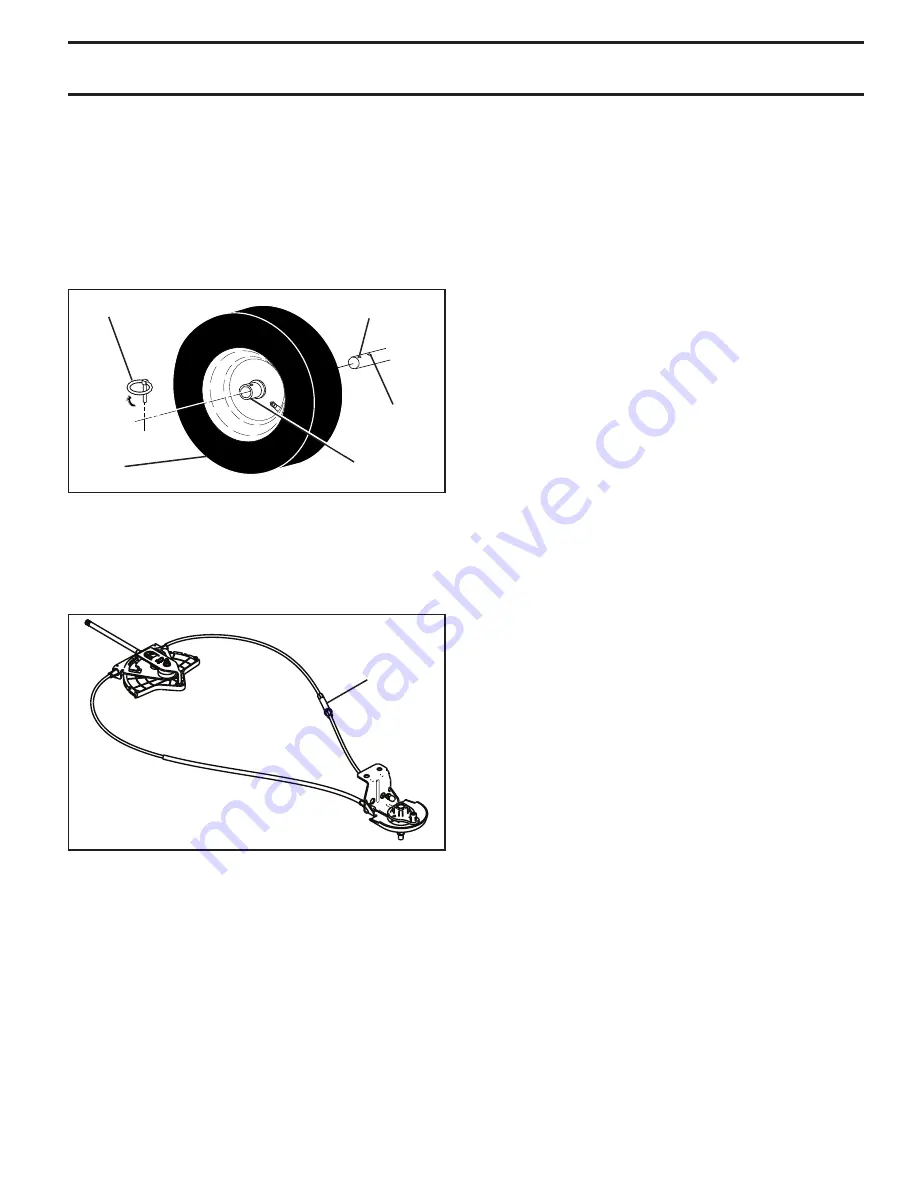

INNER

HOLE

KLIK PIN

OUTER HOLE

WHEEL HUB

WHEEL

FIG. 21

TO REMOVE WHEELS (See Fig. 21)

• Remove the klik pin and remove wheel from axle.

IMPORTANT:

When installing wheel, be sure to use the in-

nermost hole in axle and the wheel hub hole. To dis en gage

drive system from the wheels (for pushing or trans port ing

the snow thrower), remove klik pin from wheel hub and

insert pin into the outermost hole in axle only.

NOTE:

To seal punctures or prevent flat tires due to slow

leaks, tire sealant may be purchased from your local parts

dealer. Tire sealant also prevents tire dry rot and cor ro sion.

TO ADJUST CABLE TENSION (See Fig. 22)

Adjust cable tension by turning the adjuster turn buckle,

located on the right hand cable. Grasp the long section

tightly and turn the short section to lengthen the adjuster.

Adjust until cable is snug.

ADJUSTER TURN

BUCKLE

FIG. 22

ENGINE

SEE ENGINE MANUAL.

CARBURETOR

Your carburetor is not adjustable. Engine performance

should not be affected at altitudes up to 2,134 meters. If

your engine does not operate properly due to suspected

carburetor problems, take your snow thrower to a service

center/department.

ENGINE SPEED

Never tamper with the engine governor, which is factory set

for proper engine speed. Overspeeding the engine above

the factory high speed setting can be dangerous and will

void the warranty. If you think the engine-governed high

speed needs adjusting, contact a service center/depart-

ment, which has the proper equipment and experience to

make any necessary ad just ments.

Содержание 11527SB

Страница 1: ...11527SB 11527SB Operator s Manual ...

Страница 24: ...532 43 58 82 06 23 10 TH Printed in the U S A ...