19

HUSKYTOOLS.COM

Please contact 1-888-43-HUSKY for further assistance.

Maintenance

GENERAL MAINTENACE

All repairs should be performed by an authorized service representative.

WARNING:

Disconnect, tag, and lock out the power

source, and then release all pressure from the system

before attempting to install, service, relocate, or perform

any maintenance.

1

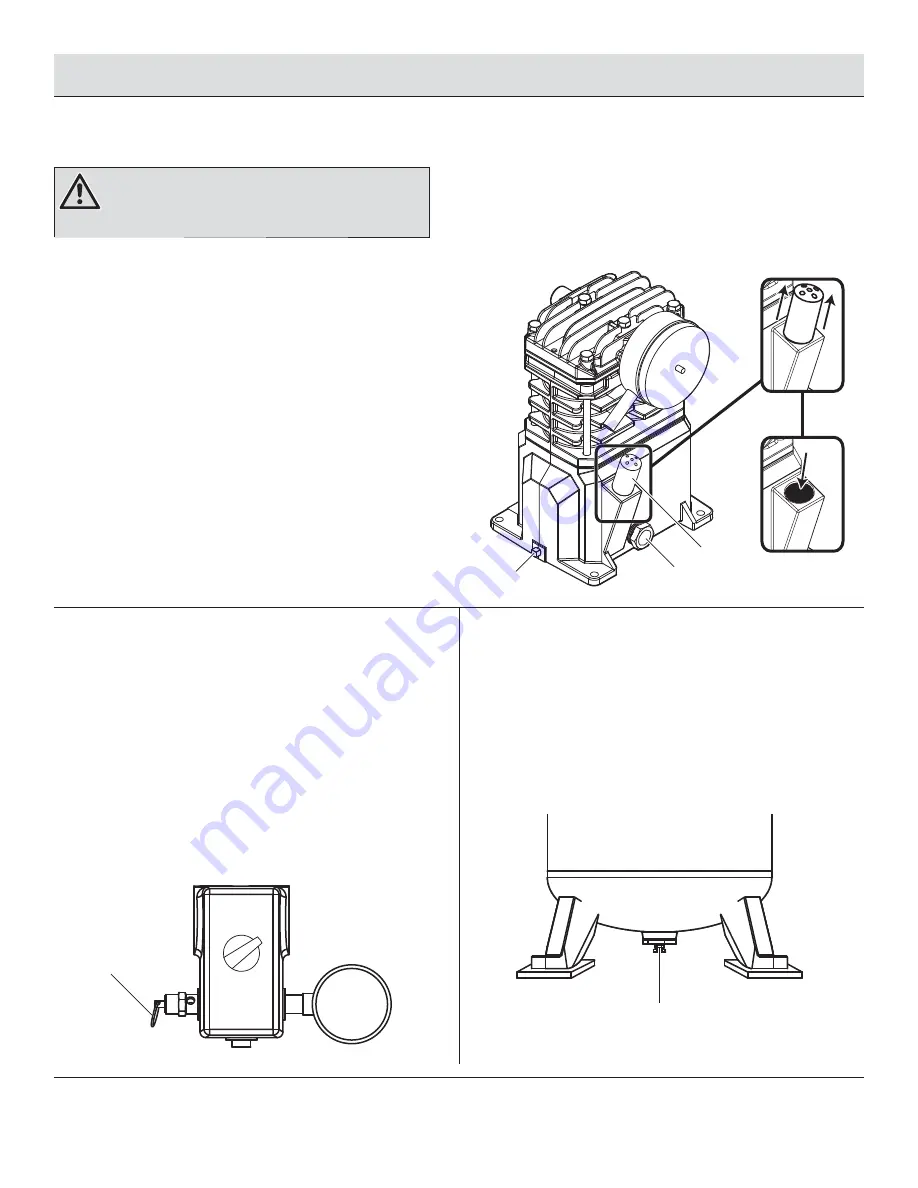

Checking and changing the oil

Maintain the proper oil level by checking the oil sight glass (1)

daily. Change the oil in the pump every 3 months. Use the following

procedure to change (or add) oil.

□

Run the compressor for ten minutes to warm up the oil if the

unit has not been in use for an extended period of time.

□

Turn the compressor off and disconnect the compressor

from the power source.

□

Position a pan under the pump drain plug (2) to catch the oil.

□

Remove the pump drain plug (2) and allow the oil to collect

in the pan.

□

Reinsert the oil drain plug. Remove the breather (3) from the

pump. Pour new, unused oil into the pump. Do not overfi ll.

□

Reinsert the breather (3) into position. Return power to the

compressor for use.

2

Checking the ASME safety valve

□

Run the air compressor until it reaches cut-out pressure.

□

Turn the compressor off and disconnect the compressor

from the power source.

□

Put on safety glasses. Protect yourself from fast moving air.

□

Pull on the ring of the ASME safety valve (1). This

releases pressure from the tank. The safety valve should

automatically close at approximately 40 - 50 psi.

If the safety valve does not allow air to be released when you

pull on the ring, or if it does not close automatically, it MUST be

replaced.

3

Draining the tank of moisture

□

Turn the compressor off and disconnect it from the power

source.

□

Release the pressure from the compressor by pulling on

the ASME safety valve. The ASME safety valve should close

at approximately 40 - 50 psi.

□

Open the drain valve (1) underneath the tank. Remaining

air pressure will assist in removing moisture from the tank.

2

1

3

1

1