10

JIN04MKIIC_V1 10/01/17

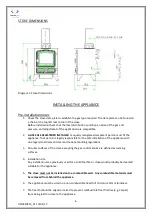

GAS SUPPLY CONNECTIONS

The appliance is supplied with an 8mm Bundy pipe and

an 8mm compression elbow to allow easy connection

to the mains gas supply. This supply gas pipe should

incorporate a gas service isolation tap that is situated

within 1 metre of the application.

Photo 3: The 8mm Bundy pipe being fitted to the gas

inlet on the valve. The compression joint is tightened

with a 14mm open-ended spanner.

TESTING SUPPLY PRESSURE

1.

Gas pressure at the appliance is measured via the test point on the tube going to the control

valve (circled in diagram 3b).

Turning the screw approximately half a turn anti-clockwise with a small flat-bladed screwdriver opens

the test point.

ALWAYS CLOSE TEST POINTS AFTER USE!

2.

The gas pressure at the appliance is measured with the appliance running at

full rate

.

(For information on how to achieve ‘full rate’ read ‘Adjusting Between High and Low Output Settings’ in

the ‘Lighting the Appliance’ section of the User Instructions).

Burner Gas Pressure should be:

19mbar ± 1.0mbar for Natural Gas

3. The supply pressure test point (shown in diagram 3a) is on the left-hand side of the control valve.

Diagram 3a: Supply Pressure Test Point.

Diagram

3b:

Burner Pressure Test Point.