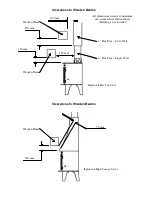

Material Clearances

The stove can be recessed in a suitable sized fireplace but a permanent free air gap of at least 150mm

must be left around the sides and top and at least 50mm at the back of the stove to obtain maximum heat

output and for access to the rear of the stove.

All non-combustible walls closer than 300mm to the stove should be at least 75mm thick.

In all instances the hearth and back wall of the fire place should be made of non-combustible material.

Allow an apron of a least 300mm at the front of the stove and 150mm on either side.

The hearth on which the stove is to be placed should not be less than 125mm thick and should be in

accordance with the current building regulations.

Care should be taken to level the stove using the adjusting screws in the feet.

The appliance shall be installed on a floor with adequate load-bearing capacity. If the existing

construction does not meet this prerequisite, suitable measures (e.g. load distributing plate) should be

taken to achieve it.

MINIMUM DISTANCE TO COMBUSTIBLE MATERIAL

Behind the stove

600mm

At the side of the stove

300mm

There should be

NO

furniture placed within

900mm

from any surface of the Stove.

Note: Combustible material refers to any material that will degrade when subject to heat. E.g. plaster

Note: walls and hearth are non-combustible and all dimensions stated are minimum.

150mm

50mm

125mm

300mm

75mm