B

.

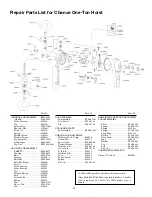

Housing Sub-Assembly

(E309-0477) and related parts.

(1) Examine "stop" surfaces, the

mating surfaces to the handle

"stops". Reasons for damage

and possible malfunctions are

the same as outlined in section

A, part (1). Replace housing

if damaged or worn. Refer to

Fig. 5.

(2) Housing Hook should be re-

placed if the hook has been

sprung or bent by misuse. Refer

to disassembly instructions for

replacement procedure.

Excessive hook play in the

housing may be an indication

that the bearing seat in the

aluminum housing is worn, in

which case, replace the housing.

Refer to Fig. 6 for correct hook

adjustment.

(3) Shift key (P309-0043) should

be examined for breakage or

bending, particularly the cam-

ming surfaces. Fig. 7 and Fig.

8 show the correct position of

the shift key when the shift

key finger (19296) is in "up" or

"dn" position.

(4) Shaft (P309-0791). Factory re-

placement of this part is seldom

necessary on hoists returned for

repair. Replacement is general-

ly required because of extreme

mistreatment of the hoist:

Breakage of the ratchet teeth

caused by severe shock loading,

or repeated self-ratcheting; us-

ing the hoist as a maul; foreign

matter carried into the chain

pockets and wedging, causing

breakage of the chain pocket

sides. Fig. 9 & 10.

Damaged Housing

Adjust screw so that

spring does not bind

on unloader plate.

7

FIG. 7 Shift Key in "Up" Position

FIG. 8 Shift Key in "Down" Position

Hook Safety

Latch

New Housing

FIG. 5

FIG. 6 Safety Hook Housing

Insert groove

pin through

hole in hous-

ing.

Tighten nut to allow

minimum clearance

when safety latch is

pivoting back for disen-

gagement.

Check pin for wear

or bending

Slight marking caused

by contact with stop

bolt is normal. Replace

if damaged.

Battered

"Stop" Area