Disassembly Instructions for Periodic Inspection

and Repair or Replacement of Parts for One-Ton Hoist

5

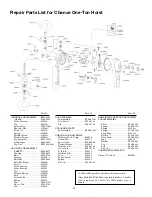

In order to best visualize these

instructions, study and refer to the

exploded view of the hoist.

7. In replacing the housing dog, make

1. Remove bolt (P001-0997) from

shaft (P309-0791). Remove cap

(P309-0822), washer (P001-1485)

& spacer (P309-0325) if used.

2. Push "release key" (P309-0346) in

the indented area of the handle in

the direction marked "release" to

disengage the handle dog (E309-

0354) from the unloader plate

and lift handle (P309-0816) off

the shaft. This will expose the

mechanism.

3. The housing dog (E309-0354) may

be removed by first removing

screw (56013) and washer (56014)

from the post supporting the dog.

Torsion spring (56010) can be re-

moved, after the dog, if needed.

4. When reassembling handle dog

(E309-0354) and spring (56010),

place the short leg of the spring

to the pin on the dog, and the long

leg of the spring against handle

housing (P309-0816).

5. If necessary to replace the dog

post (PSP309-0910) or release key

(P309-0346) remove nut (56748)

and press the dog post out of

housing (P309-0816) with a care-

ful and steady force. In replacing

the new dog post, be certain it is

pressed in straight, using an even

pressure, and that release key is

in position before pressing post

into housing.

6. The housing dog (E309-0354) can

be removed by unhooking the long

extension spring (56009) from the

unloader plate (E309-0356) and

screw (56163) in the housing and

the short extension spring (P309-

0352) from the dog post and spring

anchor pin (P309-0347). Remove

snap ring (56011) and remove

unloader plate and lift dog (E309-

0354) off post.

To remove Interlocking Snap Ring,

pry one end apart using screwdriver.

Parts may fly away when Ring un-

snaps.

To reassemble, follow these instructions

in the reverse manner replacing parts

in the same position as noted when

removed. It is important that the hoist

be inspected, cleaned, and relubricated

periodically depending on working con-

ditions.

sure the pin which is permanently

secured to the dog is faced to the

To reinstall, hook one end and close

with pliers.

outside, so that it will project

through the unloader plate, when

unloader plate is replaced on the

shaft.

8. To remove shaft (P309-0791) (the

ratchet gear and chain socket are

integral), remove ring (056871)

and free the end of the chain

(19353). This will allow the chain

to be "pulled" through the housing.

Then by removing interlocking

snap ring (56011), the shaft can

be slid through its bearing.

9. Hook (19562) is assembled to

housing (P309-0476) and the nut

is pinned in place. If hook is to be

replaced, it must be sawed through

shank adjacent to the top of the

housing.

10. The shift key (P309-0043) can

be removed by backing out the

drive-lock pin (59036) holding

the shift key finger (19296) to the

shift key.

11. The Oilite bearings (58613, 58614,

19305) can be removed and re-

placed by pressing them out and

pressing the new ones in.

Periodic Maintenance

The hoist is designed to provide rugged

service. Initiating a program of periodic

inspection, cleaning, and repair will in-

crease the service life of the hoist.

Time intervals between routine clean-

ing and inspection will depend entirely

upon severity of usage and the environ-

ment in which the hoist is operated. A

program of regular maintenance can

best be determined by the user to suit

his particular needs.

degree of mechanical aptitude. Sound

judgment must be exercised in determin-

ing degree or extent of repairs necessary.

Replacing a single faulty part in an other-

wise worn assembly is not as desirable as

an an extensive rebuild. Hoists returned

to the A. B. Chance Company for repair

are thoroughly cleaned, checked, and

rebuilt to "near new" condition.

Without question, any hoist not func-

tioning properly or showing external

damage should be tagged as defective

and sent to the repair area.

Extensive repairs should be attempted

only by personnel with a reasonable