106

M 830 LL - M 830 M

User Manual

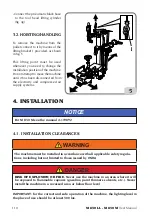

1.5. EMPLOYEE TRAINING

1. The employer is obligated to provide a programme to train all employees who service

rim wheels in the hazards involved in servicing those rim wheels and the safety procedures

to be followed. Service or servicing means the mounting and demounting of rim wheels,

and related activities such as inflating, deflating, installing, removing and handling.

• The employer shall insure that no employee services any rim wheel unless the em-

ployee has been trained and instructed in correct procedures of servicing the type of

wheel being serviced, and in safe operating procedures.

• Information to be used in the training programme shall include, at a minimum, the ap-

plicable information contained in this manual.

2. The employer shall ensure that each employee demonstrates and maintains the ability

to service rim wheels safely, including performance of the following tasks:

• Demounting tyres (including deflation).

• Inspecting and identifying rim wheel components.

• Mounting tyres.

• Using any restraining device, cage, barrier, or other installation.

• Handling rim wheels.

• Inflating the tyre.

• Understanding the necessity to stand back from the tyre changer during tyre inflation

and during inspection of the rim wheel following inflation, never leaning over.

• Installing and removing rim wheels.

3. The employer shall evaluate each employee’s ability to perform these tasks and to

service rim wheels safely, and shall provide additional training as necessary to assure

that each employee maintains his or her proficiency.

1.6. PRE-USE CHECKS

Before beginning work, carefully check that all components of the machine, especially

rubber or plastic parts, are in place, in good condition and working properly. If the inspec-

tion reveals any damage or excessive wear, no matter how slight, immediately replace

or repair the component.

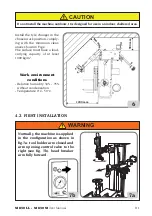

1.7. DURING USE

In the event you hear any strange noise or feel unusual vibration, if a component or

system is not operating properly, or if there is anything unusual at all, stop using the

machine immediately.

• Identify the cause and take any necessary remedial action.

• Contact your supervisor if necessary.

Never allow any bystander to be within 20 feet of the machine during operation.

To stop the machine in an emergency:

• disconnect the power supply plug;

• cut off the compressed air supply network by disconnecting the shut-off valve (snap

coupling).

Содержание M 830 LL

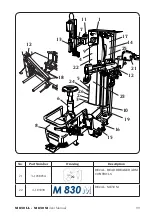

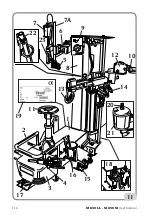

Страница 30: ...116 M 830 LL M 830 M User Manual 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 19 22 7A 11 18 20 21 23...

Страница 37: ...M 830 LL M 830 M User Manual 123 A B C 1 2 D 17...

Страница 38: ...124 M 830 LL M 830 M User Manual A B C D 1 2 2 18...

Страница 49: ...M 830 LL M 830 M User Manual 135 1 2 3 4 30...

Страница 76: ...162 M 830 LL M 830 M User Manual M13 M14 M11 M7 M2 M9 A M16 STANDARD RIM...

Страница 77: ...M 830 LL M 830 M User Manual 163 M6 M5 M11 M7 M9 B M16 DROPPED CENTRE HOLE RIM...

Страница 78: ...164 M 830 LL M 830 M User Manual C M11 M2 REVERSED RIM...

Страница 79: ...M 830 LL M 830 M User Manual 165 D M10 M2 M15 M9 PICK UP RIM...

Страница 80: ...166 M 830 LL M 830 M User Manual E CLOSED CENTRE RIM...

Страница 81: ...M 830 LL M 830 M User Manual 167 F OPEN CENTRE RIM...

Страница 84: ...170 M 830 LL M 830 M User Manual...

Страница 85: ...M 830 LL M 830 M User Manual 171 49...

Страница 86: ...172 M 830 LL M 830 M User Manual Note...

Страница 87: ...M 830 LL M 830 M User Manual 173 Note...