10

Removal and replacement procedures

Adherence to these procedures and precautions is essential for proper service.

Preparation for disassembly

Use this information to properly prepare to disassemble and reassemble the monitor.

Use this information to properly prepare to disassemble and reassemble the monitor.

1) Clean the room for disassembly.

2) Identify the disassembly area.

3) Check the position that the monitors are to be placed along with the number of

monitors. Prepare the area for material flow according to the disassembly layout.

4) Be sure to have the following equipment and materials:

•

Press fixture

•

Working table

•

Screwdriver

•

Knife

•

Gloves

•

Cleaning cloth

•

ESD protection

•

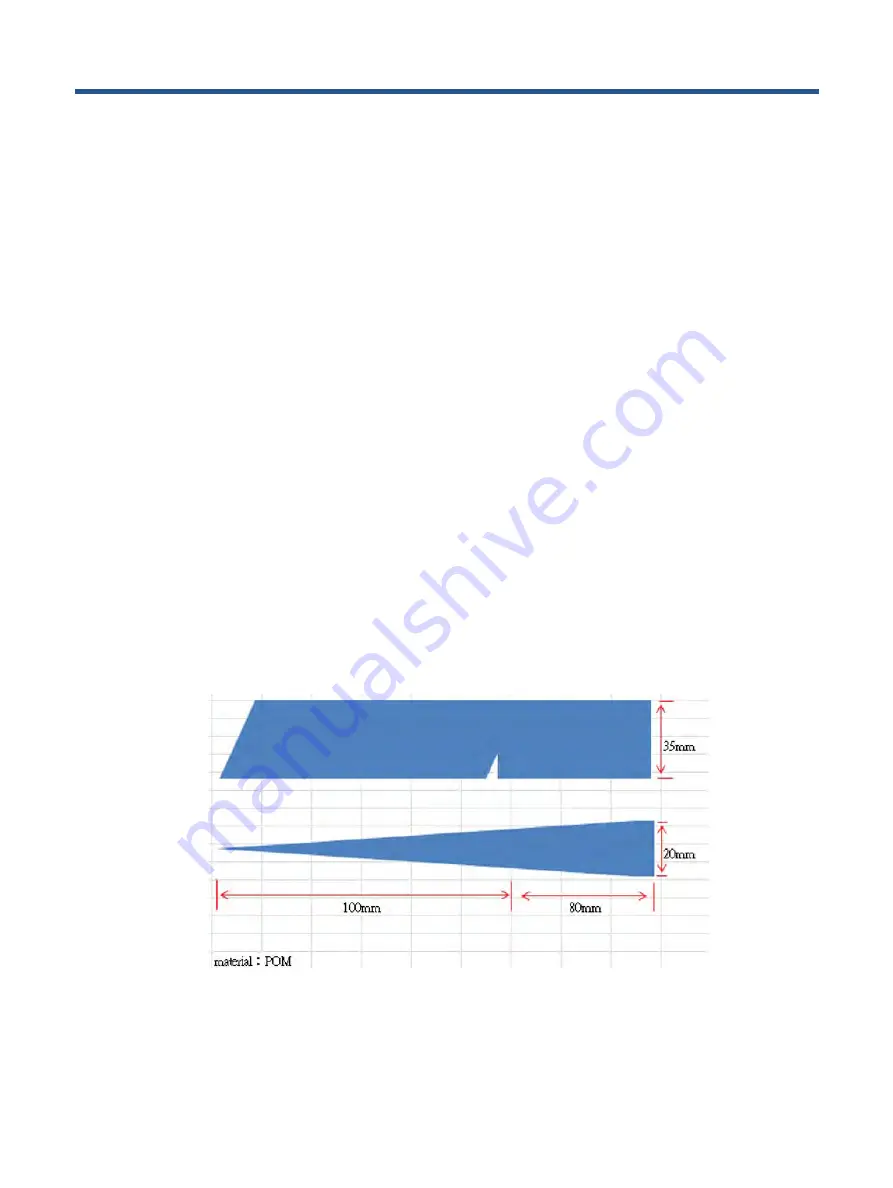

Scraper bar in the following dimensions:

Содержание L55527-001

Страница 7: ...5 Front View ...

Страница 24: ...22 Support and Troubleshooting ...