8 Adjusting the substrate tension

EN

Adjusting the substrate tension

You can optimize the rewinder performance by adjusting the substrate tension.

Using the tension control panel

From the tension control panel, you can do the following:

z

To control the tension of the finished roll, adjust the web tension controller. The default

setting is 0.5 bar for thin substrates and 2.5 bar for thick substrates. Set the web

tension controller according to the properties of the substrate (see tables 1-3

and 1-4).

z

To reduce the amount of wrinkles in the finished roll, adjust the riding arm controller.

The default setting is 2 bar.

z

To control the nip pressure, adjust the nip controller. The default setting is 4 bar. For

smooth or glossy substrates, increase the nip pressure.

z

To control the pulling force of the rewinder, adjust the dancer arm controller. The

default setting is 0 bar.For thick substrates, increase the dancer arm controller.

z

To use the counter, see "Using the meter counter" on page 9.

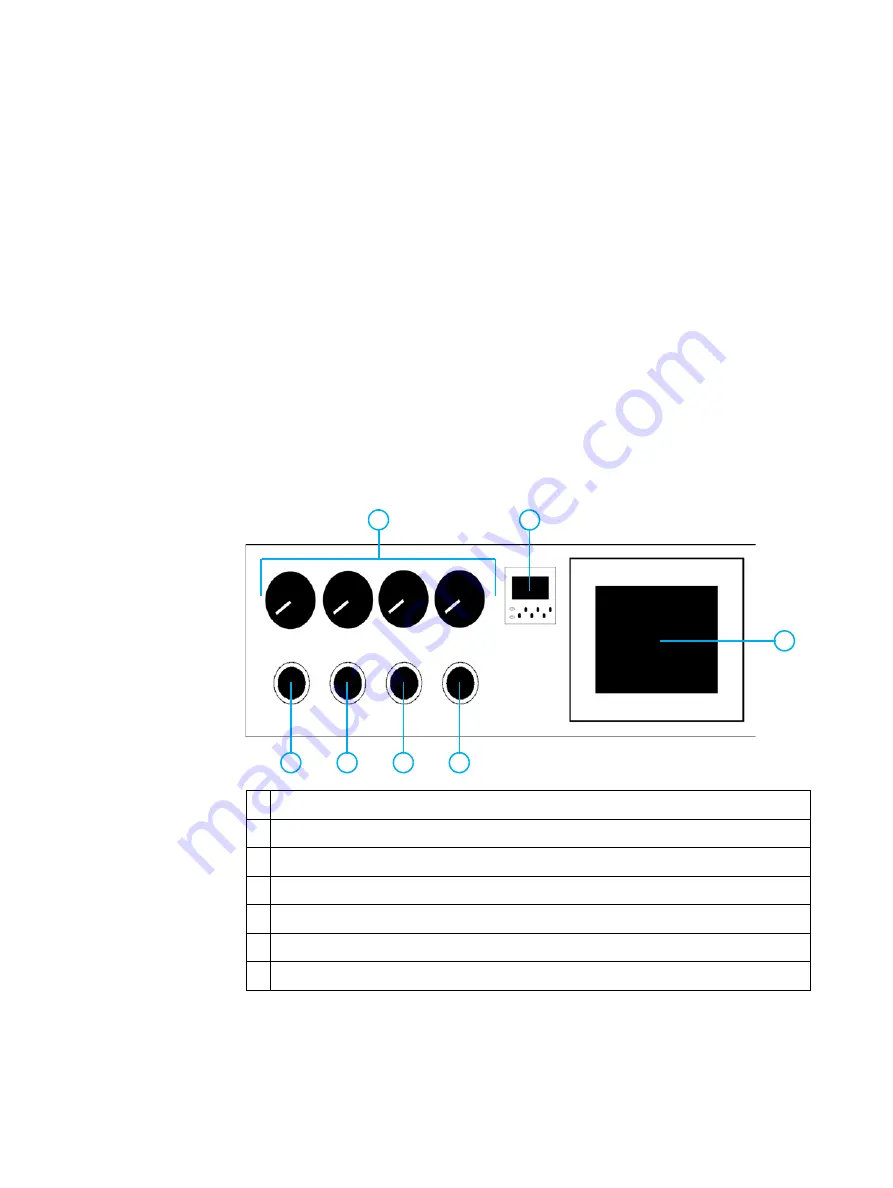

Figure 1-8. Tension control panel

1

Controller displays

2

Meter counter

3

Touch screen

4

Dancer arm controller

5

Nip controller

6

Riding arm controller

7

Web tension controller

1

7

6

5

4

2

3