7

ISRB-2009, Rev. 02_17.

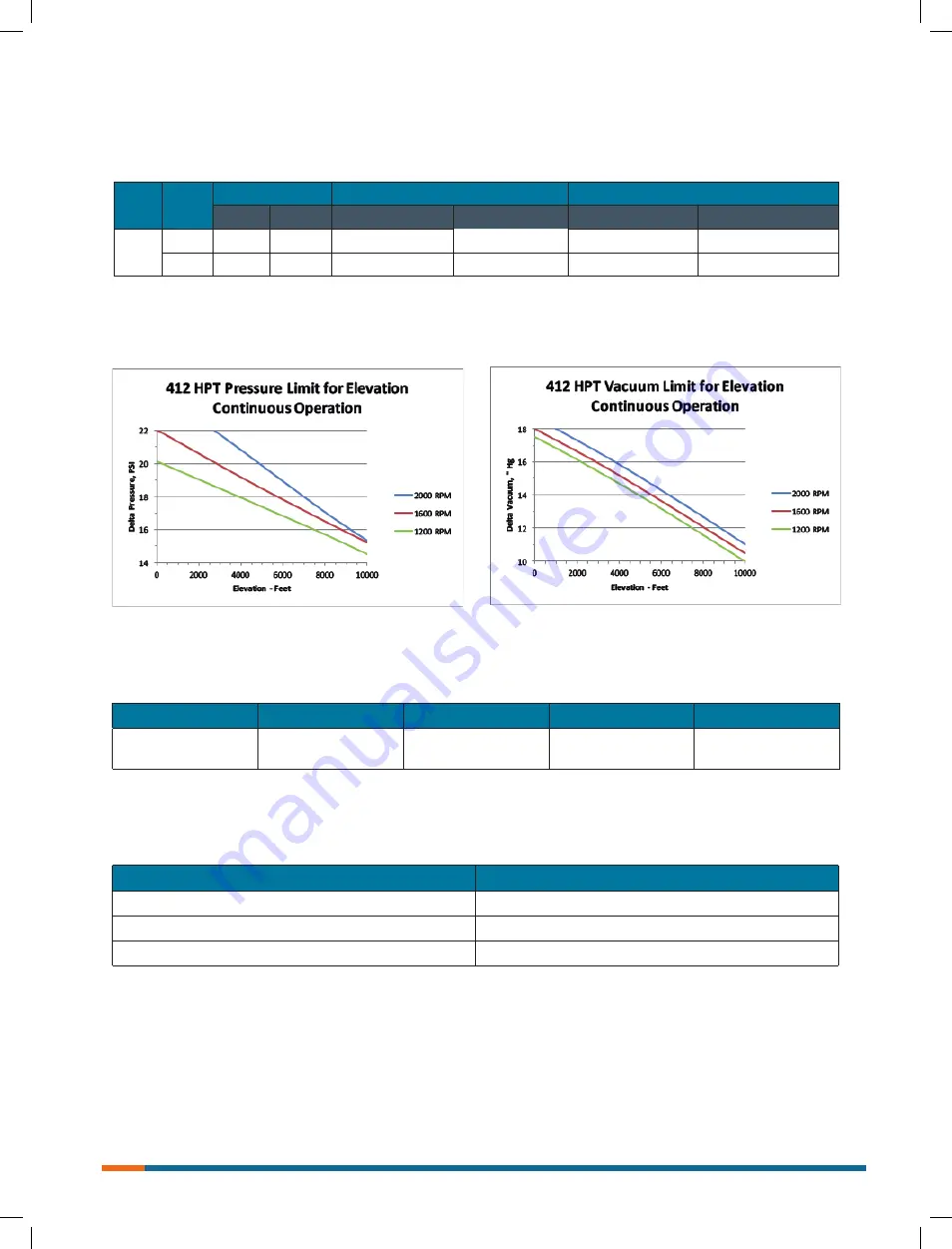

Table 1, Maximum Allowable Operating Conditions

Model Speed

Temperature rise

Pressure Rise

Vacuum

o

F

O

C

PSI

mbar

''Hg

mbar

412

HPT

2000

335

168

22 (continuous)

1517 (continuous)

18 (continuous)

609 (continuous)

2000

335

168

25 (intermitten)

1725 (intermitten)

19 (intermitten)

643 (intermittent)

NOTE: Limited to minimum 1600 RPM operation at 22 PSI continuous pressure, or 18'' Hg continuous vacuum

at sea level conditions.

NOTE: Maximum intermittent pressure occurs @ 3 PSI above continuous pressure limit.

TE

OTE

Inlet

Fronts

Backs

.005 - .007

(.13-.18)

.020 - .027

(.51 - .69)

.005 - .008

(.13 - .20)

.014 - .016

(.36 - .41)

.011 - .014

(.28 - .36)

Table 2, Unit internal clearances, inches (mm)

Blower discharge temperature

Oil grade - ISO

32

o

F to 100

o

F (0

o

C to 38

o

C)

100

100

o

F to 250

o

F (38

o

C to 120

o

C)

150

Over 250

o

F (120

o

C)

220

TABLE 3, Oil Grade Requirements

Содержание Roots 412 HPT

Страница 1: ...www howden com Roots 412 HPT Blower Installation Operation Maintenance Manual...

Страница 11: ...11 ISRB 2009 Rev 02_17...

Страница 12: ...ISRB 2009 Rev 02_17 12...

Страница 13: ...13 ISRB 2009 Rev 02_17...

Страница 14: ...ISRB 2009 Rev 02_17 14...

Страница 15: ...15 ISRB 2009 Rev 02_17...