5

ISRB-2009, Rev. 02_17.

Bottom inlet, top discharge is standard orientation with CCW

rotation on input drive shaft. Blower can be mounted either

on roadside or curbside of truck chassis. Exact installation

instructions cannot be given because of the variety of truck

chassis available. See SKETCH 1 for basic details. Units are

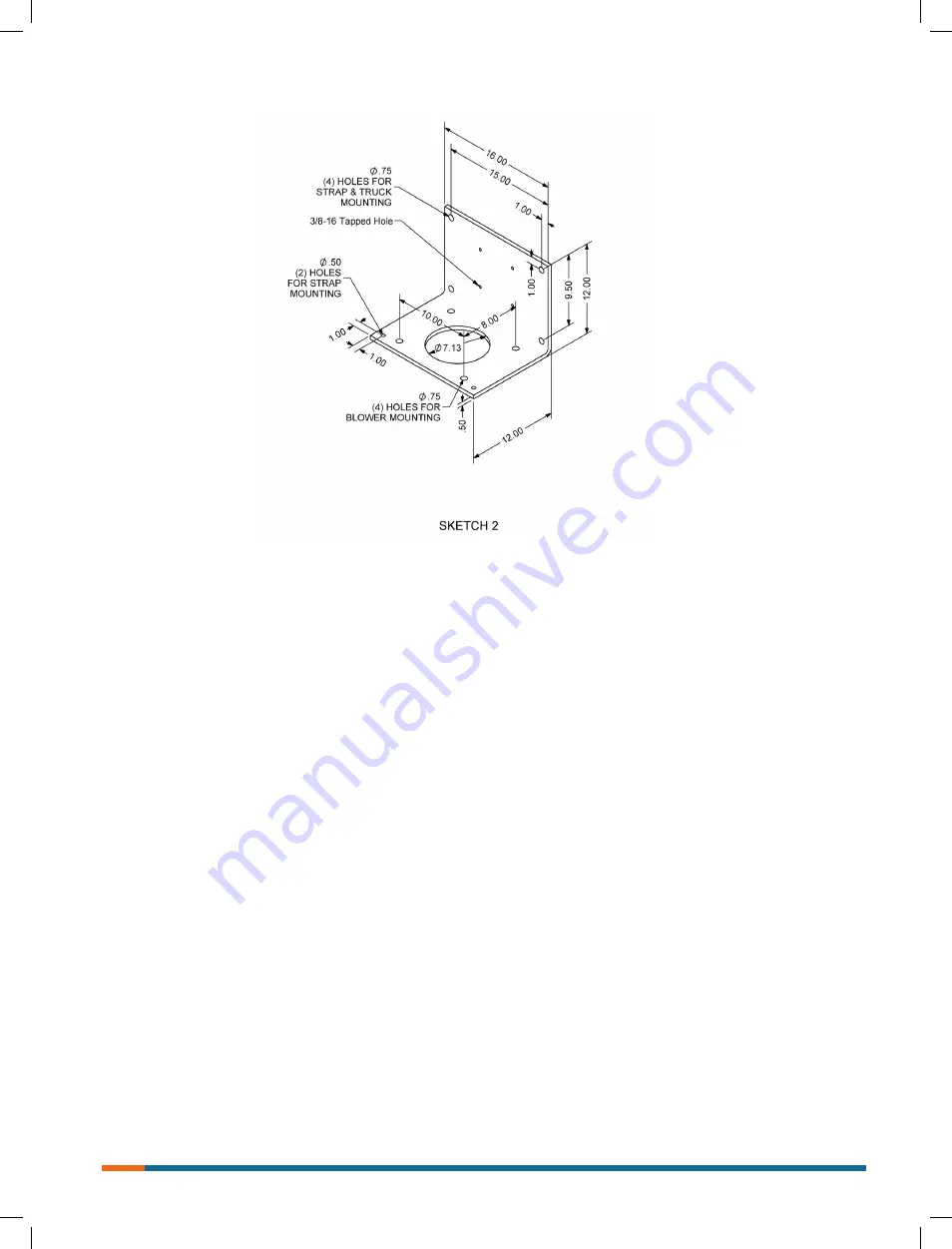

typically held in place on truck chassis by use of “L” shaped

mounting bracket; see SKECH #2 for basic details.

Check output speed range of PTO. It must be for the

blower range.

The blower should be parallel to the truck frame to minimize

vibration.

The PTO shaft must be within the manufacturer’s angularity

limits, not to exceed 5 degrees in the horizontal plane and

3 degrees in the vertical plane.

Brace mounting securely to reduce vibration.

Be sure air filter, oil level gauge, gear case breather and oil

drain plug is not obstructed for normal maintenance.

Do not weld on the blower or base, bearings can be damaged

by the passage of current.

Piping

Install an adequate air filter on blower inlet. Servicing the air

filters is one the most important maintenance operations.

Servicing frequency of filter elements is not time predictable

and must be by the user, depending on dust and moisture

conditions but pressure drop shall never exceed 20” (508 mm)

of water before servicing. Dry filter element life is typically 50

to 300 hours before replacement is necessary. Only replace,

do not reuse dry filter elements via cleaning. Do not allow oil,

grease or solvents to contact the element. Do not operate

blower with damaged filter seals or element. Do not operate

blower without filter element.

WARNING: All piping and accessories downstream of blower

should be rated for the internal pressures being subjected

during full operation.

Insure that inlet and discharge piping are clear, clean and

air tight. Do not allow dirt to enter the blower during piping

operations.

Pressure service, install an air relief valve in discharge line as

close to blower as possible. Vacuum service, install an air relief

valve in inlet line as close to blower as possible. Do not use

any caps, covers, plugs or valves between the blower and

relief valve.

Install a check valve in the discharge line after the relief valve

to prevent back flow of material into the blower and to prevent

reverse rotation of the blower.

Provide a discharge bypass valve to the atmosphere for air

bleed off to lower pressure when too high blower speed thus

flow is present.

Pressure service, install an accurate pressure gauge at or near

the blower discharge. Vacuum service, install an accurate

vacuum gauge at or near the blower inlet.

Install an accurate vacuum gauge or indicator at inlet so able

measure pressure drop across inlet filter.

Provide an adequate sized discharge line. Use as few of

bends as possible; when bends are necessary, use long

radius bends.

Make provisions in piping to allow for expansion as near to

the blower as possible.

Use a dust cover at the final discharge opening when hose

is removed.

Install discharge silencer after the check valve when additional

noise reduction is required.

Содержание Roots 412 HPT

Страница 1: ...www howden com Roots 412 HPT Blower Installation Operation Maintenance Manual...

Страница 11: ...11 ISRB 2009 Rev 02_17...

Страница 12: ...ISRB 2009 Rev 02_17 12...

Страница 13: ...13 ISRB 2009 Rev 02_17...

Страница 14: ...ISRB 2009 Rev 02_17 14...

Страница 15: ...15 ISRB 2009 Rev 02_17...