GB

23

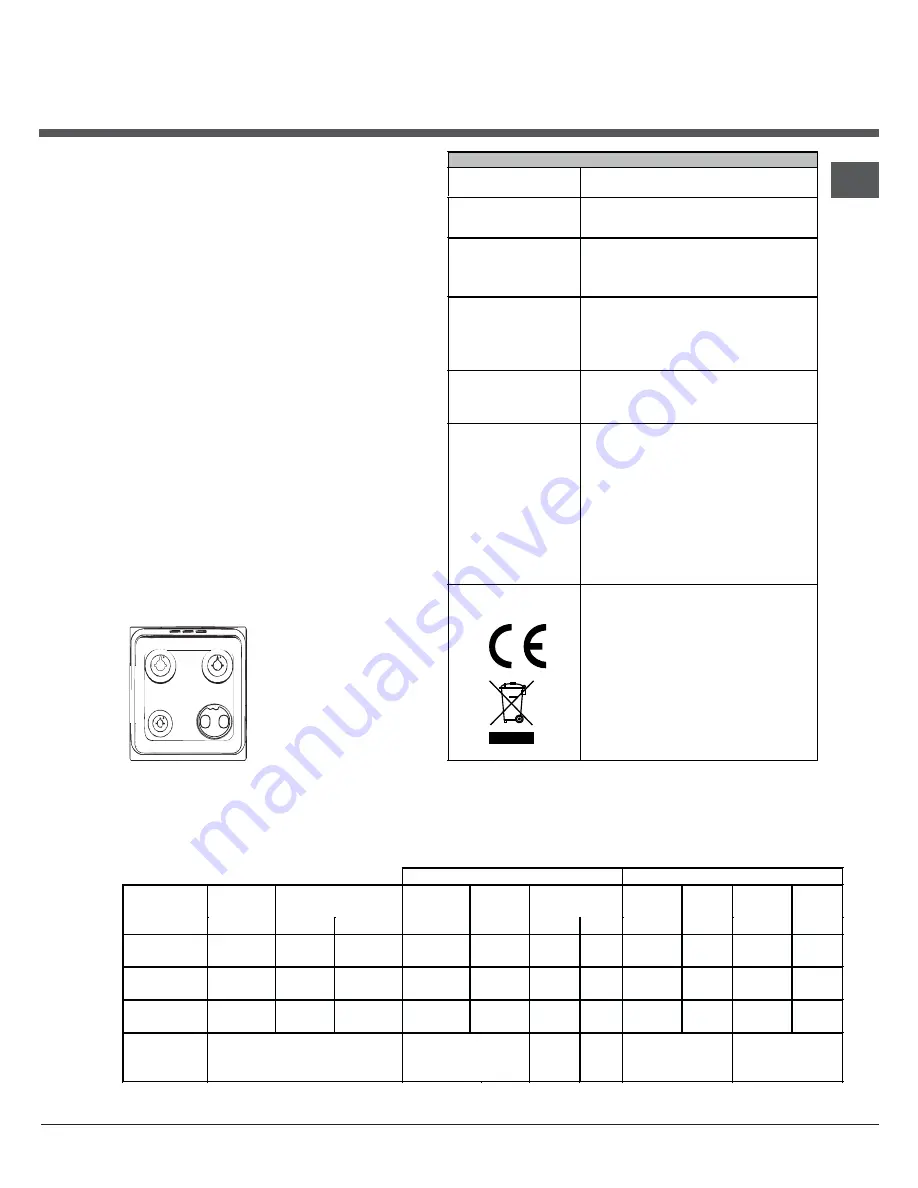

Table of burner and nozzle specifications

C35SP6R /HA S

C35SP6UA /HA S

Table 1

Liquid Gas

Natural Gas

Diameter

(mm)

Thermal Power

kW (p.c.s.*)

By Pass

1/100

Nozzle

1/100

Flow*

g/h

Nozzle

1/100

Flow*

l/h

Nozzle

1/100

Flow*

l/h

Burner

Nominal

Reduced

(mm) (mm) *** **

(mm) (mm)

Triple

Crown (TC)

309 2x107 309

Semi Fast

(Medium)(S)

75 1.90 0.4

30 70 138

136 104 181 118 181

Auxiliary

(Small)(A)

51 1.00 0.4 30 52 73

71 76 95 80 95

Supply

Pressures

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

28-30

20

35

37

25

45

20

17

25

13

6,5

18

*

At 15°C 1013 mbar-dry gas

***

Butane P.C.S. = 49,47 MJ/Kg

** Propane P.C.S. = 50,37 MJ/Kg

Natural P.C.S. = 37,78 MJ/m³

TABLE OF CHARACTERISTSICS

Dimensions

Oven HxWxD

34xx38x41

Volume

59 l

Useful

measurements

relating to the oven

compartment

width 42 cm

depth 44 cm

height 17 cm

Burners

may be adapted for use with any type of

gas shown on the data plate, which is

located inside the flap or, after the oven

compartment has been opened, on the

left-hand wall inside the oven.

Voltage and

frequency

see data plate

ENERGY LABEL

Directive 2002/40/EC on the label of

electric ovens.

Standard EN 50304

Energy consumption for Natural

convection – heating mode:

Traditional mode;

Declared energy consumption for

Forced convection Class – heating

mode:

Baking mode.

This appliance conforms to the following

European Economic Community

directives: 2006/95/EC dated 12/12/06

(Low Voltage) and subsequent

amendments - 2004/108/EC dated

15/12/04 (Electromagnetic

Compatibility) and subsequent

amendments - 93/68/EC dated 22/07/93

and subsequent amendments.

2002/96/EC

2009/142/EC of 30/11/09 (Gas)

1275/2008 (Stand-by/ Off mode)

3. Having adjusted the flame to the required low

setting, while the burner is alight, quickly change

the position of the knob from minimum to

maximum and vice versa several times, checking

that the flame does not go out.

4. Some appliances have a safety device

(thermocouple) fitted. If the device fails to work

when the burners are set to the low flame setting,

increase this low flame setting using the adjusting

screw.

5. Once the adjustment has been made, replace the

seals on the by-passes using sealing wax

!

If the appliance is connected to liquid gas, the

regulation screw must be fastened as tightly as

possible.

!

Once this procedure is finished, replace the old

rating sticker with one indicating the new type of gas

used. Stickers are available from any of our Service

Centres.

!

Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet pipe (in

order to comply with current national regulations).

S S

TC

A

130 3.25 1.50 63

2x65

236

232 2x99

Data plate, is located inside the flap or, after the oven

compartment has been opened, on the left-hand wall

inside the oven.

Содержание C35SP6R /HA S

Страница 71: ...71 SK ...

Страница 72: ...72 SK 05 2012 195103667 00 XEROX FABRIANO ...