18

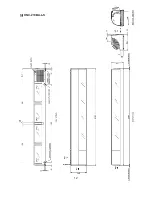

[d] SIDE FRAME

Remove the sliding door, side cover and top cover. Unbind the wiring on the side frame.

Remove the two screws securing the top frame and the top of the side frame. Lift the side

frame off the bottom fit.

Fig. 3

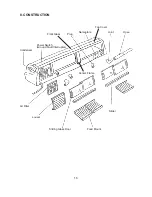

Fig. 5

Fig. 4

Truss Head Tapping

Screw 4 x 25

Truss Head Tapping

Screw 4 x 10

Holder -

Evaporator Pipe

Evaporator Pipe

[e] CENTER FRAME (Except HNC-120 type)

Remove the two flat head machine screws

(black) securing the center frame to the rear

and the two machine screws securing the

center frame to the top frame. Tilt the center

frame and release it from the fit.

[f] HOLDER - EVAPORATOR PIPE

Remove the truss head tapping screw (4 x 25)

from the bottom of the top frame. Take off the

center frame. Be careful with the evaporator

pipe. It will be released and hang down.

Remove the truss head tapping screw (4 x 10)

from the bottom of the top frame.

[g] UNIT

Remove the sliding door, side cover, top

cover, top frame and side frame. Take off

the compressor terminal cover and remove

the starter and motor protector. Uninsulate

the expansion valve and unbraze the outlet

pipe with a gas burner (see “11. CONSTANT

P R E S S U R E E X PA N S I O N VA LV E A N D

REFRIGERANT CHARGE”).

Unbraze the joint indicated. Remove the four

machine screws securing the unit base. The

whole unit can be pulled out.

Outlet Pipe

Joint

Expansion Valve

Содержание HNC-120BA-L-S

Страница 10: ...6 5 DIMENSIONS a HNC 120BA L S...

Страница 11: ...7 b HNC 120BA R S...

Страница 12: ...8 c HNC 150BA L S...

Страница 13: ...9 d HNC 150BA R S...

Страница 14: ...10 e HNC 180BA L S...

Страница 15: ...11 f HNC 180BA R S...

Страница 16: ...12 g HNC 210BA L S...

Страница 17: ...13 h HNC 210BA R S...