19. Tighten the horizontal bolts with metal guards on both sides with the

11mm lock nuts. It is important to tighten both sides evenly.

20. Check belt tightness. Adjust tightness by loosening or tightening lock

nut on horizontal bolt. To measure the belt tension, a timing belt

tension gauge is required. The correct belt tension tolerance is 120-

140 lbs. If a belt tension gauge is not available, the drive belt should

have about 0.25” deflection when pressing down firmly on the drive

belt.

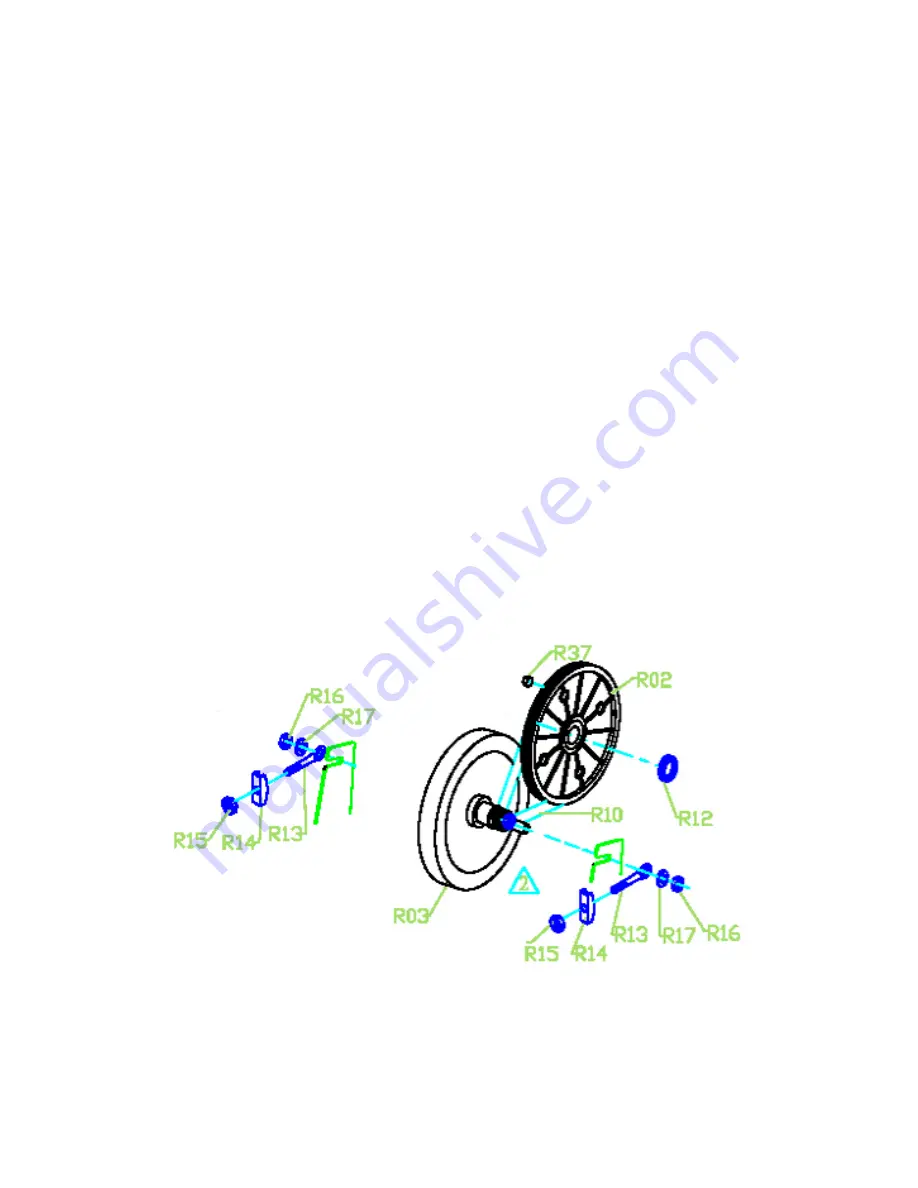

21. Once the belt tension is set properly, tighten the 17mm nuts on both

sides of the flywheel.

22. Attach the right and left side covers and secure with screws.

23. Replace wood grain accent piece.

24. Attach crank arms and crank disks and secure with 14mm nut. Place

black crank disk cap over 14mm nut.

25. Slide console mast boot back into place.

26. Attach pedal arms onto crank arms and secure with 17mm nut.

27. Attach the crank arm covers, secure with screws.

28. Attach the lower handlebars to the pedal arms and secure with bolt

and washers.

29. Attach the lower handlebar to the lower link arm using the 13mm nut

and associated bolt.

30. Test ride elliptical to make sure it is working correctly.

54