Sensor-Controller Systems

70-6925

135

H

u

m

idi

st

at

s

an

d

Th

er

m

o

st

at

s

Controller

s

Sensors

Relay

s

Switch

es

Actuators

Va

lv

e

s

Ac

ces

sor

ie

s

En

gi

ne

eri

ng

Gu

ide

Cr

o

s

s

Refere

nc

e

The humidistat can be used in a one-pipe or two-pipe

configuration and is available as either a bleed-type humidistat

or a two-pipe capacity humidistat using a capacity amplifier. The

humidistat may be direct or reverse acting. The high-capacity

humidistat has a capacity amplifier.

Pressure Controllers

Pressure controllers can be divided into two classes according

to the pressure range of the measured variable. High-pressure

controllers measure and control high pressures or vacuums

measured in pounds per square inch or in inches of mercury

(e.g., steam or water pressures in an air conditioning system).

Low-pressure controllers measure and control low pressures

and vacuums measured in inches of water (e.g., pressure in an

air duct).

High- and low-pressure controllers have different size

diaphragms. In both types, one side of the diaphragm is

connected to the pressure to be controlled, and the other side is

connected to a reference pressure. Pressures can be

measured in respect to atmospheric pressure or another

pressure source. The low-pressure controller is available in

both bleed-type and pilot-bleed designs.

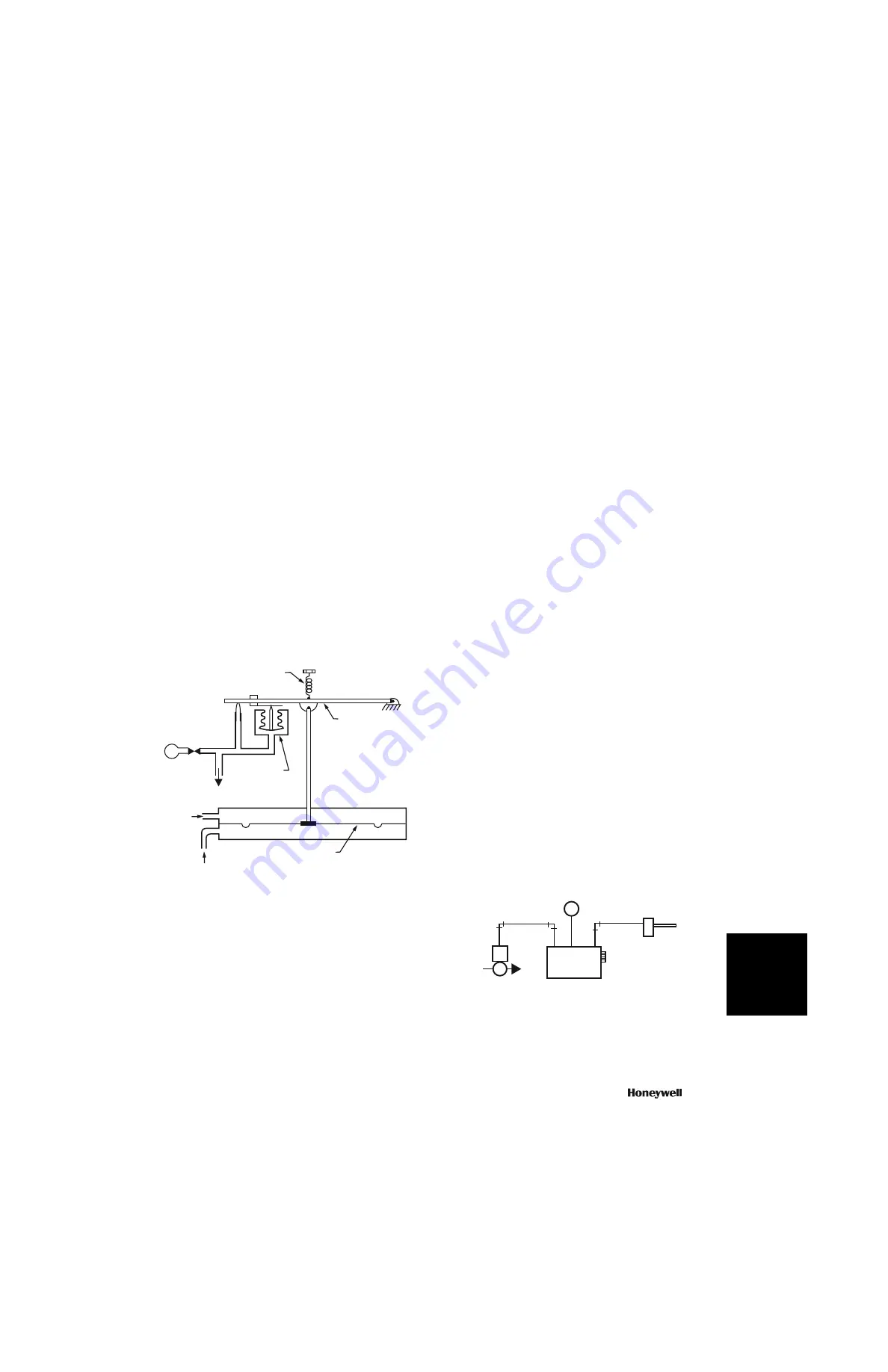

Figure 20 shows a schematic of a bleed-type, low-pressure

controller. The direct-acting pressure sensor measures static

pressure from a pressure pickup located in a duct. A reference

pressure, from a pickup located outside the duct, is applied to

the other side of the diaphragm.

Fig. 20. Bleed-Type Static Pressure Controller.

On an increase in static pressure, the increased force on the

diaphragm exceeds the force of the setpoint spring, pulling the

main lever downward. A setpoint adjustment screw determines

the tension of the setpoint spring. As the main lever is pulled

downward, it moves closer to the nozzle, restricts the airflow

through the nozzle, and increases the pressure in the branch.

The action continues until the pressure on the feedback bellows

balances the static pressure on the diaphragm.

On a decrease in static pressure, or if the static pressure sensor

is piped for reverse action (high- and low-pressure pickups

reversed), the diaphragm moves upward to move the main

lever away from the nozzle and reduce the pressure in the

branch.

For differential pressure sensing, the two pressure pickup lines

connect to opposite sides of the pressure sensor diaphragm.

SENSOR-CONTROLLER SYSTEMS

A sensor-controller system is made up of a pneumatic

controller, remote pneumatic sensors, and a final control

element. The controller provides proportional or proportional

integral control of temperature, humidity, dew point, or pressure

in HVAC systems. Sensors do not have a setpoint adjustment

and provide a linear 3 to 15 psi signal to the controller over a

fixed sensor range. The controller compares the sensor input

signal with the setpoint signal. The difference is the pilot input to

a signal amplifier, which provides a branchline pressure to the

controlled device. Thus the controller acts as a general purpose

pneumatic amplifier.

Pneumatic Controllers

Controllers generally use diaphragm logic, which allows flexible

system application, provides more accurate control, and

simplifies setup and adjustment for the needs of each system.

Controllers may be proportional only or proportional-integral

(PI). The integral function is also called “automatic reset”.

Proportional and PI controllers are available with single sensor

input or dual-sensor input for resetting the primary sensor

setpoint from a second sensor. They are also available with

integral or remote setpoint adjustment.

The single-input controller consists of a signal amplifier feeding

a capacity amplifier. The capacity amplifier is discussed under

PILOT BLEED SYSTEM. A dual-input controller has inputs from

a primary temperature sensor and a reset temperature sensor.

The reset sensor resets controller setpoint. Reset can be

negative or positive.

Figure 21 depicts a single-input controller as it would appear in

a simple application. Figure 22 depicts a dual-input controller

with manual remote setpoint control. In Figures 21 and 22 the

sensors are fed restricted main air from the controllers. Where

sensors are located extremely remote from the controller, a

remote restrictor may be required.

Fig. 21. Single-Input Controller.

PRESSURE SENSOR

REFERENCE

PRESSURE

STATIC

PRESSURE

C2609

SETPOINT

SPRING

DIAPHRAGM

M

BRANCH

FEEDBACK

BELLOWS

MAIN LEVER

M

SINGLE INPUT

CONTROLLER

HOT WATER

VALVE

MAIN AIR

(18 PSI)

TEMPERATURE

SENSOR

M10293

Содержание VP525C

Страница 58: ...50 customer honeywell com 70 6925 ...

Страница 120: ...112 customer honeywell com 70 6925 ...

Страница 166: ...158 customer honeywell com 70 6925 ...