ML6425, ML7425 SPRING RETURN ELECTRIC LINEAR VALVE ACTUATORS

7

63-2516—04

Auxiliary Potentiometers

The 43191679 Auxiliary Potentiometers can be used as

feedback potentiometers and to provide remote indication of

the valve position. Refer to the Installation Instructions packed

with the potentiometers.

Auxiliary Switches

CAUTION

Equipment Damage Hazard.

Improper voltage will damage the auxiliary switch

beyond repair.

Use the 43191680 Dual Auxiliary Switch only with 24

Vac applications.

The 43191680 Dual Auxiliary Switch can be used on both the

ML6425 and ML7425 Electric Linear Valve Actuators.

Switching points are adjustable over the full length of actuator

stroke; for example, the switch can be used to switch pumps or

provide remote indication of any stroke position. Refer to the

Installation Instructions packed with the auxiliary switch.

OPERATION

In the actuator, the drive of a synchronous motor is converted

into the linear motion of the actuator stem by using a spur gear

transmission. A button retainer clip connects the actuator stem

to the valve stem.

An integrated spring package limits the stem force to a factory

adjusted value in either direction. Installed microswitches turn

off the actuator when the specified stem force is reached.

The ML6425, ML7425 Spring Return Valve Actuators provide a

safety valve position in the event of power failure. On power

failure, the ML6425A and ML7425A extend the actuator stem;

the ML6425B and ML7425B retract the actuator stem.

The actuators are shipped from the factory with a spring

handle retaining clip installed, so the actuator can be

connected to the valve without applying power. Remove this

clip after the actuator is installed. (Refer to the Installation

section.)

ML7425

Signal Input (+)

The analog input signal (+) range is set at the factory to 0 to 10

Vdc. Changing the position of the W2 selector plug sets the

range to 2 through 10 Vdc. Selector plugs W1, W2, and W3 are

positioned on the back side of the printed circuit board. Refer

to Fig. 15 for location of the selector plugs.

Signal Input Failure

Using selector plug W1, the actuator can be set to run to one of

three positions in event of a signal failure:

• 0% Actuator position corresponds with 0 or 2 Vdc signal.

• 50% Actuator stem in mid-position.

• 100% Actuator position according to 10 Vdc signal.

NOTE: W1 is factory set at the mid-position.

Output Signal Feedback (F)

An analog output signal (2 to 10 Vdc) that represents the actual

actuator stem position is available at terminal F. It can be used

for remote indication of the stem position. When the valve stem

is fully downward, the output signal is 10 Vdc.

When the valve stem is up, the output signal is 0 or 2 Vdc. The

output of the signal does not change when the action of the

actuator is reversed using W3. See Direction of Action.

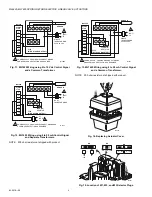

Actuator Override

To override the control signal (for freeze protection or similar

applications), connect the 24 Vac common (T2) to either

terminal O1 or O2. Connecting to terminal O1 fully extends the

actuator stem. Connecting to O2 fully retracts the actuator

stem.

The control signal (+) is ignored when the override signal is

applied to Terminal O1 or O2. This override can be achieved

with a switch or a relay (See Fig. 16).

Fig. 16. Connections for Overriding Control Signal to Drive

ML7425 to a Specific Position.

Direction of Action

The direction of actuator action can be changed by

repositioning selector plug W3, which is factory set so that the

actuator drives the valve stem down on increasing signal and

draws it up on decreasing signal. When the valve stem is up,

the output signal from the feedback (F) function is 0 or 2 Vdc.

The output of the signal does not change when W3 is used to

reverse the action of the actuator (Refer to Fig. 15).

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

F

+

0-10Vdc OR 2-10 Vdc CONTROL SIGNAL. SEE SIGNAL

INPUT (+) SECTION.

SEE OVERRIDE SECTION FOR DETAILS ON

OVERRIDE OPERATION.

2-10 Vdc FEEDBACK SIGNAL. SEE OUTPUT SIGNAL

FEEDBACK SECTION.

ML7425

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

3

4

2

INPUT

(FEEDBACK)

OUTPUT

3

2

SP3T

OVERRIDE

SWITCH

4

1

L1

(HOT)

L2

–

M7906A