Maintenance

HON 670 / HON 671 Controllers Component Documentation

25

Figure

Step

Description

4

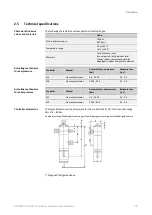

Put a new piston (2) in place.

Risk of confusion! Please observe the

characterizing difference between the old

and the new piston.

Old piston (1):

Castellated nut closed

New piston (2):

Castellated nut open

5

Put on the cap nut (1).

Counter the diaphragm plate (2) and

tighten the cap nut firmly. Tightening

torque: 20 Nm (15 ft lbs)

When doing so, the castellated nut of the

new piston will close.

6

Turn the double diaphragm system over.

Put the new diaphragm (3) and the dia-

phragm plate (2) in place.

Counter the diaphragm plate and tighten

the hex nut firmly (1). Tightening torque:

20 Nm (15 ft lbs)

7

Make sure that the diaphragm is aligned

correctly: The side of the diaphragm that

has a depression at the center should be

facing downward.

Proceed as follows:

Figure

Step

Description

1

To align the diaphragm plate correctly:

Turn the diaphragm plate all the way to the

right.

Mark this position.

Mounting the controller