W

innox · Edition 12.20

EN-2

Audience and Purpose

This manual has been written for people who are al-

ready familiar with all aspects of a gas burner and its add-

on components, also referred to as “the burner system”.

These aspects are:

– Installation

– Use

– Maintenance

The audience is expected to have previous experience with this

type of equipment.

The purpose of this manual is to make sure that you carry out the

installation of a safe, effective, and trouble-free system.

Further documents

For further information about this product see Technical Information

safety instructions

Information that is relevant for safety is indicated in the instructions

as follows:

DAnGeR

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARnInG

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUtIon

Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

All interventions may only be carried out by qualified gas techni-

cians. Electrical interventions may only be carried out by qualified

electricians.

safety

Important notices which help provide safe burner operation will be

found in this section. To avoid personal injury and damage to the prop-

erty or facility, the following warnings must be observed. All involved

personnel should read this entire manual carefully before attempting

to start or operate this system. If any part of the information in this

manual is not understood, contact Honeywell before continuing.

DAnGeR

The burners covered in this manual are designed to mix fuel with

oxygen and burn the resulting mixture. All fuel burning devices

are capable of producing fires and explosions when improperly

applied, installed, adjusted, controlled or maintained.

– Do not bypass any safety feature; fire or explosion could result.

– Never try to light the burner if it shows signs of damage or

malfunction.

WARnInG

– The burner is likely to have HOT surfaces. Always wear

protective clothing when approaching the burner.

– Honeywell products are designed to minimize the use of

materials that contain crystalline silica. Examples of these

chemicals are: respirable crystalline silica from bricks, cement

or other masonry products and respirable refractory ceramic

fibers from insulating blankets, boards, or gaskets. Despite

these efforts, dust created by sanding, sawing, grinding,

cutting and other construction activities could release crystal-

line silica. Crystalline silica is known to cause cancer, and

health risks from the exposure to these chemicals vary

depending on the frequency and length of exposure to these

chemicals. To reduce the risk, limit exposure to these chemi-

cals, work in a well-ventilated area and wear approved person-

al protective safety equipment for these chemicals.

CAUtIon

– This manual gives information for the use of these burners for

their specific design purpose. Do not deviate from any

instructions or application limits in this manual without written

advice from Honeywell.

Capabilities

Only qualified personnel, with good mechanical aptitude and ex-

perience with combustion equipment, should adjust, maintain, or

troubleshoot any mechanical or electrical part of this system.

operator training

The best safety precaution is an alert and trained operator. Train

new operators thoroughly and have them demonstrate an adequate

understanding of the equipment and its operation. A regular retraining

schedule should be administered to ensure operators maintain a

high degree of proficiency.

Replacement Parts

Order replacement parts from Honeywell only. Any customer-sup-

plied valves or switches should carry UL, FM, CSA, CGA and/or CE

approval where applicable.

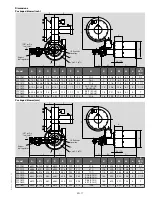

PRoDUCt DesCRIPtIon

The Winnox is a nozzle-mix, low-emissions burner designed for

direct and indirect air heating, as well as oven applications up to

1800°F (980°C).

The burner package includes a combustion air blower and ratio

regulator to fire over a wide gas turndown range at a controlled ratio.

The wide variety of options and configurations are available due to

the modular design of the burner.

The burner is designed for:

– Low NO

X

and CO emissions

– Efficient ratio controlled combustion

– Reliable burner operation

– Simple burner adjustment

– Direct spark ignition

– Multiple fuel capability

IntRoDUCtIon

In this section you will find the information and instructions needed

to install the burner and system components.

Handling and storage

Handling

➔

Make sure the area is clean.

➔

Protect the components from weather, damage, dirt and moisture.

➔

Protect the components from excessive temperatures and hu-

midity.

storage

➔

Make sure the components are clean and free of damage.

➔

Store the components in a cool, clean, dry room.

➔

After making sure everything is present and in good condition,

keep the components in original packages as long as possible.

Position of Components

The position and amount of components are determined by the kind

of control method chosen. All the control methods can be found here:

Technical Information Winnox - System Design. Use the schematics

in that chapter to build your system.

Approval of Components

Limit Controls and safety equipment

All limit controls and safety equipment must comply with all applicable

local codes and/or standards and must be listed for combustion

safety by an independent testing agency. Typical application ex-

amples include:

– American: NFPA 86 with listing marks from UL, FM, CSA

– European: EN 746-2 with CE mark from TuV, Gastec, Advanti-

ca