Troubleshooting

DB-Series | Version 3.09

15

3. Occasionally unscrew the tailstock spindle, clean it

and spray it with dry lubricant. Grease the threaded

spindle.

4. Check the clamping of the tailstock and tool rest and

readjust if necessary.

5. Check drive belt and replace if necessary. The check

should be carried out after approx. 100 operating

hours.

10.3Servicing

As a result of wear and tear, servicing work may have to

be carried out on the machine.

Lubrication

The belt cover must be removed to lubricate the shift and

drive shafts. Only an adhesive grease may be used for

this, as it can otherwise lead to malfunctions of the belt!

Guides, quills and bearings must be lubricated with com-

mercially available grease!

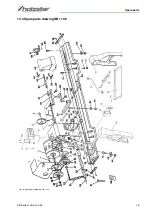

The points to be lubricated are shown in Figure 17.

Fig. 17: Lubricating points

11 Troubleshooting

ATTENTION!

Servicing work may only be carried out by qualified

personnel with mechanical knowledge.

NOTE!

During the maintenance of the lathe, all moving parts

must be lubricated at least once a month. If required,

the parts can be lubricated at shorter intervals

Lubricating points

Fault

Possible cause

Solution

Motor does not start

No mains voltage.

Check mains fuse.

Switch, capacitor are defec-

tive.

Have checked by a qualified electrician.

Electrical extension conduc-

tor is defective.

Pull the mains plug, check and replace if necessary.

Holes become larger

than the drill used.

Spindle head and tailstock

are not parallel.

Adjust spindle head to tailstock tip. To do this, insert the

face driver and the moving tailstock tip. Push the tailstock

forward and align with the points.

The workpiece is flut-

tering

Workpiece loosens during

work.

Observe the working instructions in the operating instructi-

ons.

No centering.

Observe chapter "Working instructions" in the operating in-

structions.

Speed too high.

Select a lower speed.

The tool rest or the

tailstock can no lon-

ger be clamped..

The eccentric clamp is too

loose.

Tighten the hexagon nuts on the underside.

This only has

to be in contact and not tightened

.