BA_PH_436-100_EN_44-21.docx

38

13.2

Changing the Knives on PANHANS Traditional Cutter Block (Option)

Permitted replacement knives:

35 x 3 x 630 (TYP 436|100)

Correctly ground and adjusted knives are the basic prerequisite for clean and precise working of the machine.

The following measures are generally to be applied:

•

Thoroughly clean the knives, wedge bars, contact

surfaces on the shaft as well as the contact surfaces

of the adjusting devices.

•

Sharpen, hone and balance the knives in parallel.

•

Check the knives for straightness and clean grinding

before insertion.

•

The adjustment may only be made with PANHANS

adjusting devices (see

13.2.1 or

•

Generally use only high-quality knives.

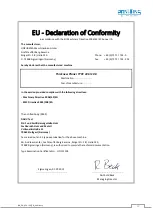

Figure 44: Traditional cutter block

•

The knives (

M

) may only be sharpened to such an extent that a minimum clamping length of 20 mm can be

maintained with a knife protrusion of max. 1 mm (see

To replace the knives, use only the PANHANS cutter adjusting devices included in the scope

of delivery or the magnetic quick adjusters (type 1533), which are available as accessories.

The manufacturer is not liable for damage caused by a deviating or improper procedure!

13.2.1

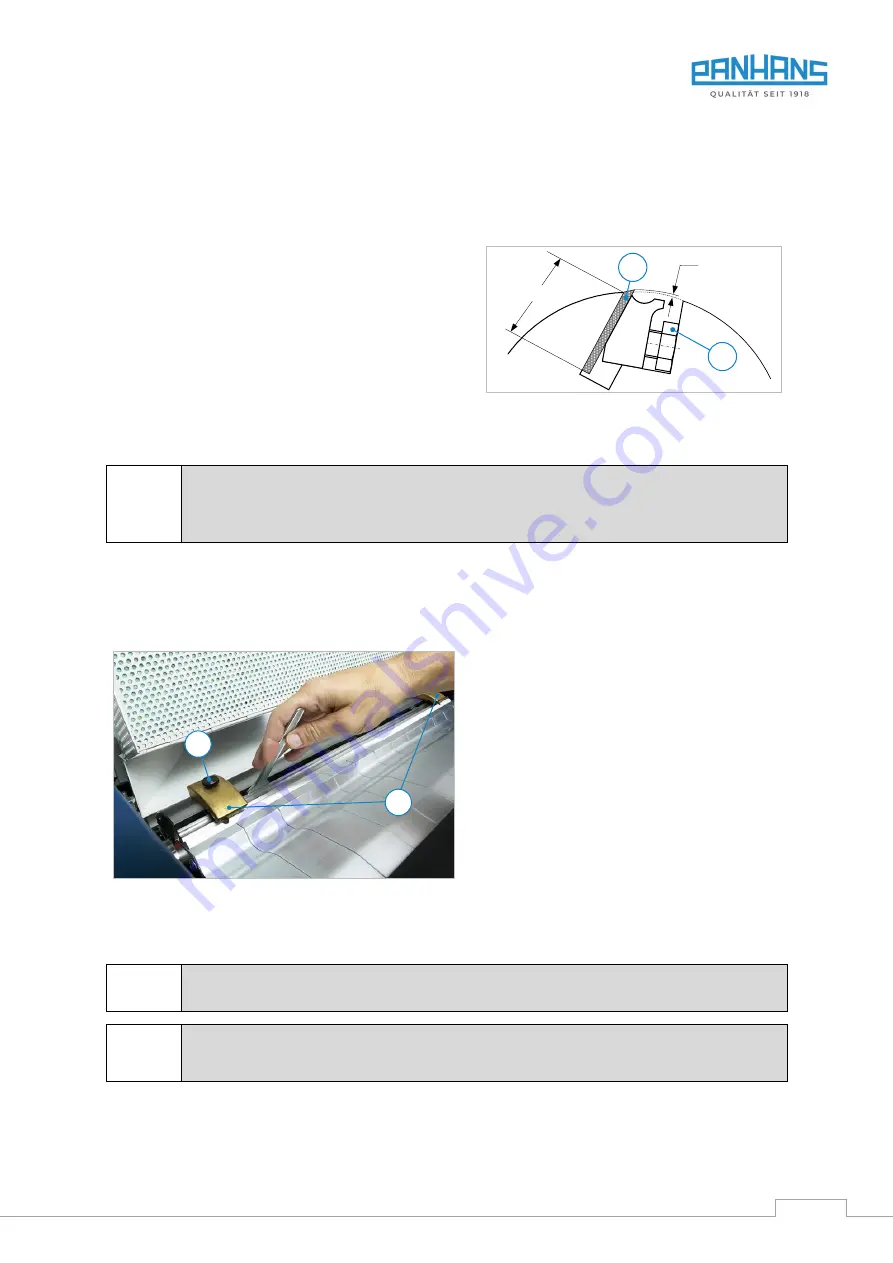

PANHANS Cutter Block Adjusting Devices

The standard cutter block adjusting devices are already included in the scope of delivery when ordering the op-

tional PANHANS traditional cutter block. The correct adjustment is carried out as described below:

Figure 45: Standard adjusting devices

•

Using a flat spanner SW17 (as shown in

45), loosen all the screws (

S

) in sequence and re-

move the blunt knives (

M

), see

•

After thoroughly cleaning all parts and contact

surfaces, insert the new or sharpened knife (

M

)

into the shaft groove and tighten lightly with two

screws (

S

).

•

Tighten the two adjusting devices (

E

) with the

knurled screws (

R

) in the threaded holes of the

cutter block.

•

Loosen the two screws (

R

) again

→

The pressure

springs will force the knife against the adjusters.

•

Starting from the middle screw, tighten all the cutter head screws alternately in an outward direction.

•

After approx. 5 minutes of running, retighten the cutter head screws.

Maximum permissible knife projection over the shaft base body = 1 mm.

The optimum tightening torque for the cutter head screws is 32 Nm.

Please do not use an extension or a hammer!

Suitable replacement knives and accessories for the traditional cutter block can be found in section

min. 20 mm

max. 1 mm

M

S

E

R