BA_PH_245-20_EN_15-22.docx

62

19

Lubrication Instruction

The machine has been extensively test-run at the factory and is lubricated ready for operation. Relubrication

before commissioning is therefore not necessary. For subsequent lubrication, use only special grease, e.g.:

•

PANHANS ZET-GE-MSO

•

ARCANOL BN 102

•

CALYPSOL H 442 B

•

SHELL ALVARIA 3

For oil lubrication we recommend:

•

Motor oil 20 W 40

Always use the same grease/oil type.

•

Check all sliding or rolling parts weekly for smooth running and lubricate with a thin oil if necessary.

•

Apply weekly a few drops of oil to the threads of the clamping and adjustment levers.

19.1

Change Lubricator

The lubricator is constructed in such a way that the lubricant is dispensed within one year.

Switch off the machine before changing the lubricator and secure against unintentional

restarting! Lock the main switch with a padlock!

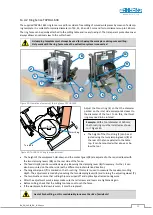

Figure 64: Change lubricator

Figure 65: Activation with activation screw

•

Open the front service door and unscrew the used

lubricator (

S

) from the lubrication point.

•

Remove the cap of the new cartridge. Release lub-

ricant dispensing by screwing in the activating

screw with a suitable tool, until the O-ring breaks

off (see

Figure 65 on the right).

•

Then shake the cartridge well to check the activa-

tion. If the activation is correct, a clear "clicking"

sound should be heard.

•

Before installation, write the replacement date

into the intended field of the lubricator label.

•

Now screw in the new lubricator by hand.

•

The lubricant dispensing period is 12 months.

Please ensure that no dust or dirt gets into the bore of the cartridge holder as long the lubri-

cator is unscrewed!

Once the lubricator has been activated, lubricant dispensing can no longer be interrupted!

Please also read the next section

“Lubrication Plan”

.

S