BA_PH_245-20_EN_15-22.docx

63

19.2

Lubrication Plan

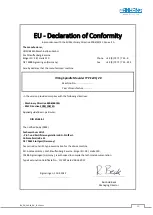

Figure 66: Lubrication points on the machine

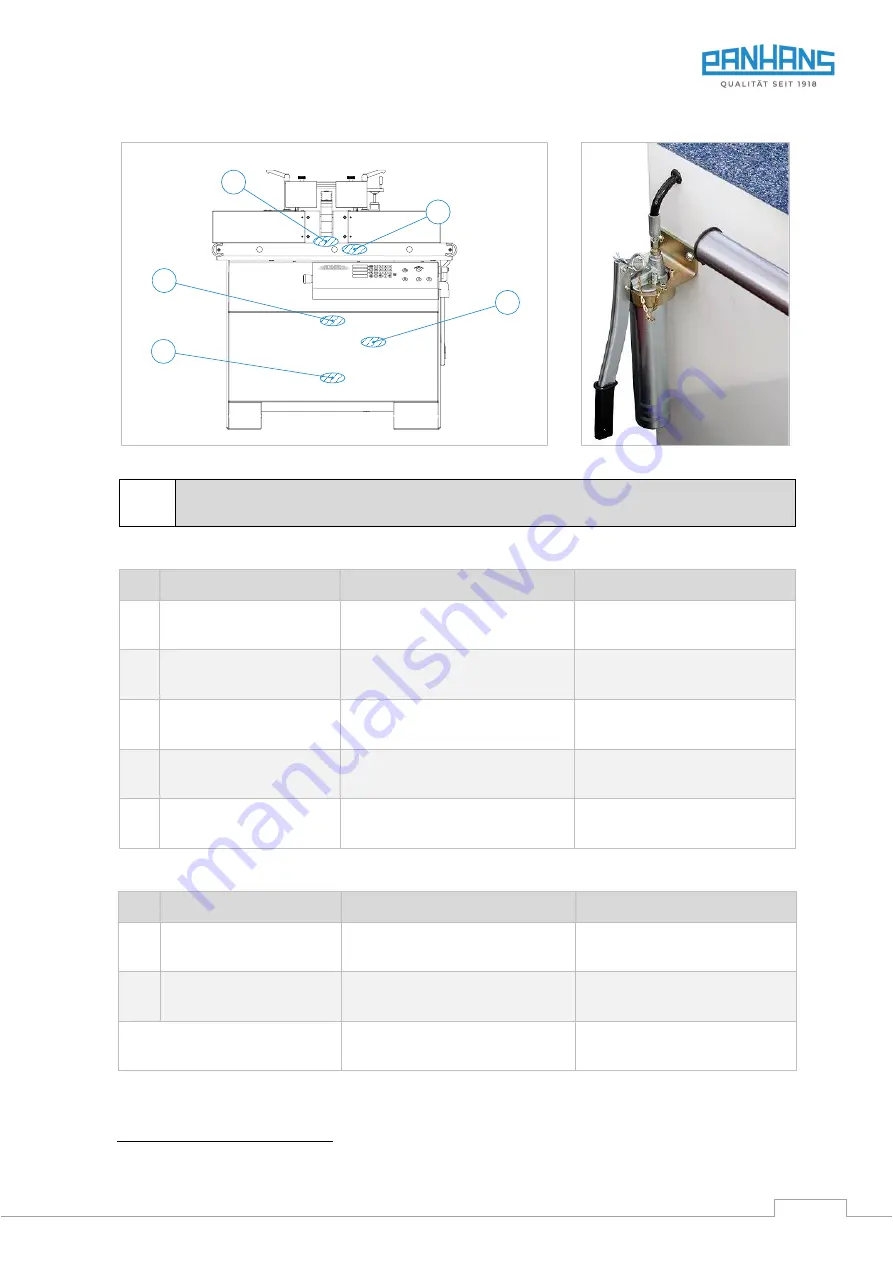

Figure 67: Central lubrication

To keep the machine parts always clean and in perfect condition, excess and/or old grease must

be wiped off at the outlet points of all existing grease nipples and other guiding elements!

Standard Version

Pos. Lubrication Point

Access

Lubrication Interval / Dosage

1

Milling spindle bearing

(top)

Move the spindle all the way up and

remove the insert rings or table slider

monthly / 2 grease shots

2

Milling spindle bearing

(bottom)

Open front service door

monthly / 2 grease shots

3

Height adjustment bearing

(top)

Open front service door

monthly / 2 grease shots

4

Height adjustment bearing

(bottom)

Open front service door

monthly / 2 grease shots

5

Swivel segment guides

7

(both sides)

Access from above, before

remove insert rings / table slider

weekly / lubricate with fine oil

With Central Lubrication (Option)

Pos. Lubrication Point

Access

Lubrication Interval / Dosage

1

Milling spindle bearing

(top)

Move the spindle all the way up and

remove the insert rings or table slider

monthly / 2 grease shots

5

Swivel segment guides

7

(both sides)

Access from above, before

remove insert rings / table slider

weekly / lubricate with fine oil

Grease gun (see

Remove the lock on the hand pump

monthly / 4 grease shots

In addition to the lubrication plan, please also refer to the section

“Maintenance Plan”

.

7

Remove resin and wood residues from the swivel segments once a week.

1

5

4

2

3