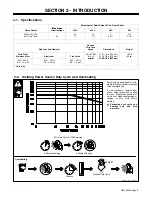

OM-192 440 Page 23

200 785-C

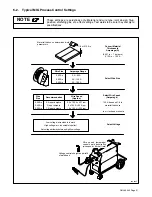

3/8”

(9.5 mm)

—

—

—

5/66

7/70

7/60

7/100

7/82

7/60

7/75

6/50

5/46

—

—

—

—

—

—

1/4”

(6.4 mm)

4/58

5/56

5/40

5/100

5/76

4/60

4/50

5/58

4/38

4/30

6/90

5/70

6/50

6/45

6/18

6/64

6/60

5/36

5/42

5/16

5/56

5/54

1/8”

(3.2 mm)

4/75

3/45

4/44

3/75

3/60

3/48

2/30

2/20

2/0

2/0

4/60

4/62

4/34

4/28

4/12

4/50

14 ga.

(2.0 mm)

3/60

3/36

3/30

3/70

2/46

2/40

2/20

2/10

3/38

3/35

3/32

3/20

3/40

16 ga.

(1.6 mm)

3/50

2/22

3/20

2/50

2/36

2/26

1/10

1/0

1/0

—

3/30

2/20

—

—

—

18 ga.

(1.2 mm)

2/36

2/16

2/10

2/40

1/22

1/10

1/0

—

2/18

2/14

—

—

—

1/0

1/0

1/0

—

—

22 ga.

(0.8 mm)

1/15

1/22

1/8

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

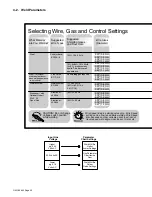

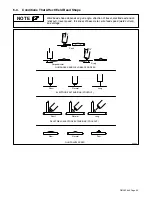

Select Voltage and Wire Speed Based

on Thickness of Metal Being Welded

SETTINGS ON THIS CHART ARE STARTING

VALUES ONLY AND ARE BASED ON A 230 INPUT

LINE VOLTAGE. SEE OWNERS MANUAL FOR

MORE INFORMATION.

1/2”

(12.7mm)

—

—

—

—

—

—

—

—

7/95

7/90

7/60

—

—

—

—

—

—

—

—

—

3/16”

(4.8 mm)

5/85

6/100

4/50

5/50

4/34

3/30

3/25

2/20

4/36

4/85

4/70

4/55

3/46

3/40

2/30

2/22

4/45

4/50

3/30

3/20

5/72

4/80

3/60

3/52

2/22

5/100

4/64

5/38

4/28

4/12

4/50

4/54

3/52

4/54

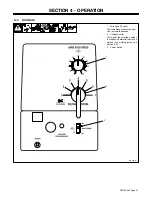

VOLTA GE

1

2

3

4

5

6

10

20

30

40

50

60

70

80

90

WIRE SPEED

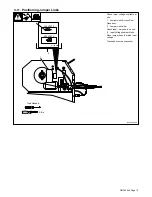

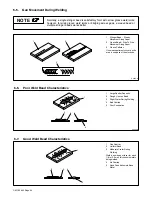

Wire Size

Stock No.

V

−

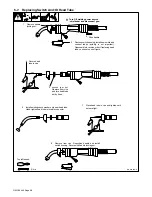

Grooved .024”,.030”/.035”

202925

.024”,.045”

407230

−

004

V

−

Knurled .030”/.035”

193330

.039”/.045”,.052”/ 1/16”

193331

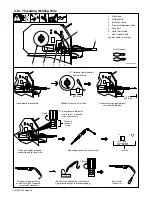

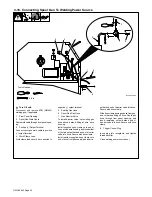

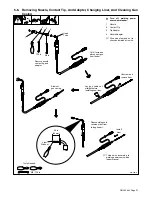

A) Nozzle

.625 orf flush

#169 726

.500 orf recess

#169 724

.625 orf recess

#169 725

.500 orf flush

#200 258

B) Tips

.625 orf stickout

#169 727

.023/0.6 mm

.030/0.8 mm

.035/0.9 mm

.045/1.1 mm

.023/.025

.030/.035

.035/.045

#169 728

#169 729

C) Contact Tip Adapter

D) Nozzle Adapter

E) Retaining Ring

F) O

−

Ring

G) Shock Washer

H) Head Tube

Liners

#170 467

#170 468

#169 730

#160 731

#194 010

#194 011

#194 012

M

−

25Consumables

DriveRolls

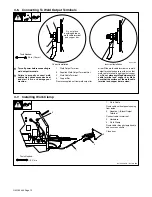

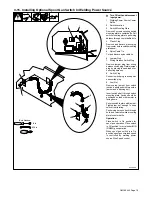

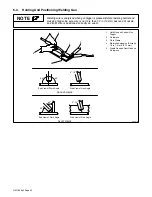

Changing Polarity

Example 2/40 =

To read settings:

Number on left of slash

is voltage,numberon

right of slash is wire

−

speed.“—” means not

recommended.

#200785C

Wi r e Drive Assembly

L e a d To Positive (+)

O u t p u t Terminal

Wo r k Clamp Lead

To N e g a t i v e (

−

)

O u t p u t Terminal

A

B

C

D

E

F

G

H

Electrode Negative (DCEN): Reverse lead connections

at terminals from that shown above for gasless flux cored

wires (FCAW). Drive assembly becomes negative.

#087 299

#000 067

#000 068

#000 069

Содержание IronMan 250

Страница 44: ...OM 192 440 Page 40 Notes ...

Страница 45: ...OM 192 440 Page 41 SECTION 7 ELECTRICAL DIAGRAM 206 590 A Figure 7 1 Circuit Diagram For Welding Power Source ...

Страница 54: ...Notes ...