--- 19 ---

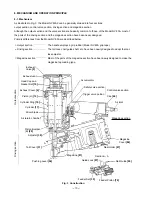

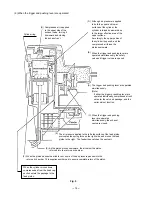

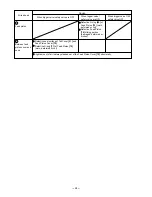

Driver blade is worn.

Problem

Possible cause

( : Most-common cause)

Inspection method

Remedy

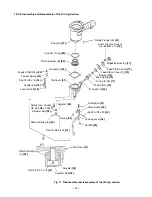

Cylinder inside surface is

abnormal (packed with

dust, or worn).

Sliding surface between the

cylinder and the cylinder

guide or sliding surface

between the cylinder and

the cylinder plate is

abnormal (seized or

damaged, or lubrication is

needed).

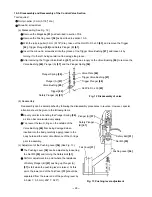

<Control valve section>

Trigger plunger, plunger (A),

safety plunger (B), trigger

valve bushing, valve

bushing or urethane ball (C)

is abnormla (seized or

damaged).

O-ring or sliding surface is

worn or needs lubrication.

Remove dust and then

lubricate.

Replace the part.

Replace the part.

Apply grease.

Replace the abnormal part.

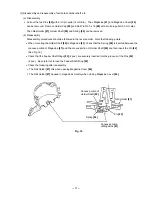

Check that nails can be

driven at 5 kgf/cm

2

(4.9 bar,

70 psi).

Perform idle driving to

check the driving

operation.

Disassemble the control

valve section and check the

O-rings.

Replace the abnormal part.

Apply grease.

See item 1).

Workpiece is too hard.

Nailer cannot be used

because the material is

beyond its applicable range.

Check if a nail is bent even

when driven into soft wood.

Check that the driver blade

tip is not abnormally worn.

See item 1).

Driver blade is worn.

Replace the part.

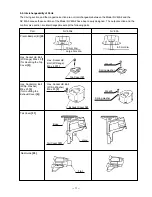

2) Nails are

driven but

bent.

Nails are not completely

fed into the injection port.

Unspecified nails are used.

Set the adjuster to the

optimum position.

Adjust air pressure to

5 --- 8.5 kgf/cm

2

(4.9 --- 8.3

bar, 70 --- 120 psi).

Nailer cannot be used

because the material is

beyond its applicable range.

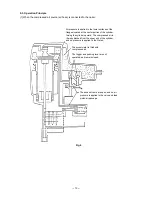

3) Nails cannot

be driven into

the workpiece

completely:

the heads

cannot be

made flush.

Adjuster is incorrectly set.

Air pressure is too low.

Workpiece is too hard.

Turn the adjuster to the

deepest driving position and

then drive nails.

Check if a nail is bent even

when driven into soft wood.

Replace the part.

Perform idle driving to check

the driver blade is pfojected

from the nose tip.

1) Nails cannot

be driven.

(continued)