--- 16 ---

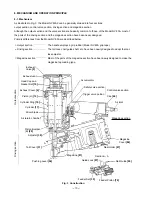

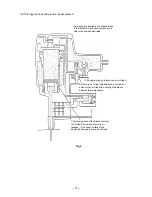

Fig. 7

The pressure on the upper surface of the exhaust valve is released, and

the exhaust valve is pushed upward by the air pressure within the

cylinder. This opens the exhaust vent, and the air pressure in the cylinder

and the left-side surface of the feed piston are discharged from the nailer.

Air pressure is discharged from the upper end of the

cylinder, and the cylinder is pushed upward by the air

pressure on the lower surfaces of the flanges and the

force of the springs. This closes the upper end of the

cylinder, and blocks further compressed air from

entering the cylinder.

At the time the piston returns, any remaining air

pressure at the lower end of the piston is

discharged through the clearance between the

tail cover and the driver blade.

When the air pressure at the upper side of the piston is reduced, the

air pressure within the return air chamber pushes the piston upward.

(Note) If the clearance were any larger, the piston

would not return: if it were smaller, driving

force would be decreased.

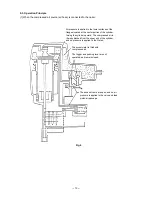

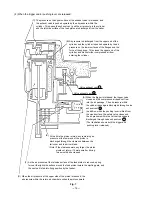

When the trigger is released, the trigger valve

closes, and the compressed air does not flow

into the air passage. The air pressure within

the valve air passage is discharged through valve

exhaust vent I .

In addition, when the pushing lever is lifted from

the wood surface, the safety valve closes and

the air pressure within the valve air passage is

discharged through valve exhaust vent II .

(The illustration shows both the trigger and

pushing lever released.)

Valve exhaust vent II

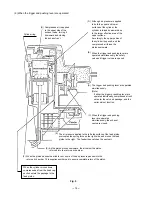

(4) When the trigger and/or pushing lever are released:

As the air pressure at the left-side surface of the feed piston is reduced, spring

force at the right-side surface moves the feed piston toward the ejecting gate, and

the next nail is fed into firing position by the feeder.

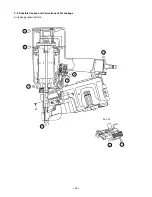

(C)

(B)

Valve exhaust vent I

(A)

(E)

(F)

(D)