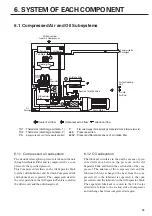

6.1 Compressed Air and Oil Subsystems

6.1.1 Compressed air subsystem

The air under atmospheric pressure is taken in the unit

through Air Intake Filter and is compressed by a com-

pressor to the specified pressure.

This Compressed Air flows in the Oil Separator Tank

together with Lubricant, and by which Compressed Air

and Lubricant are separated. The compressed air after

the oil separation in the Oil Separator Tank is cooled in

the Aftercooler and then discharged out.

6.1.2 Oil subsystem

The lubricant circulates in the unit by means of pres-

sure dif ference between the pressure in the Oil

Separator Tank and that in the suction side of the com-

pressor. The mixture of the compressed air and the

lubricant which exchanged the heat from the com-

pressed air to the lubricant is separated to the com-

pressed air and the lubricant in the Oil Separator Tank.

The separated lubricant is cooled in the Oil Cooler

afterwards, returns to the suction side of Compressor

and exchange heat from compressed air again.

PS

TH2

63E

P

TH1

63

SV

Air Exhausted

from Air Compressor

Compressed Air

Discharged

Air for Cooling

Unit

Air into

Air End

Oil

Discharge

Coolant air flow

Compressed air flow

Lubricant flow

TH1

:

Thermistor (discharge air temp. 1)

TH2

:

Thermistor (discharge air temp. 2)

PS

:

A pressure sensor (for capacity control)

P :

Pressure Gauge (For displaying oil separator tank internal pressure)

63E : Pressure switch

63SV : Pressure differential sensor of air intake filter

Air Intake Filter

Suction Throttle Valve

Compressor

Aftercooler

Oil Cooler

Fan Motor

Cooling Fan

Minimum

Pressure/

Check Valve

Oil

Separator

Oil Temperature Control Valve

Oil Filter

Main Motor

Oil Separator

Tank

29

6. SYSTEM OF EACH COMPONENT