--- 20 ---

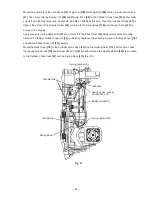

9-1-2. Reassembly

Reassembly can be accomplished by following the disassembly procedure in reverse. However, special attention

should be given to the following items.

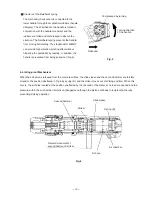

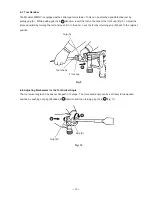

Mounting hammer holder (A)

Set the Retainer Sleeve

[16]

, O-ring (S-34)

[14]

,

Damper (A)

[17]

and Hammer Holder (A)

[18]

in the

Front Cover

[12]

. Supporting the flange portion of the

Front Cover

[12]

with a proper jig, lightly push in Ring

(B)

[20]

using a proper jig of 44 mm outside dia. and

a hand press. At this time, check that Ring (B)

[20]

is

fitted in the groove of the Front Cover

[12]

securely

(Fig. 18).

Ring (B)

Hammer holder (A)

O-ring

Retainer sleeve

Fig. 18

Damper (A)

Front cover

Proper jig

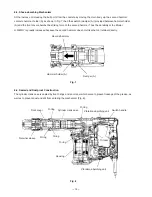

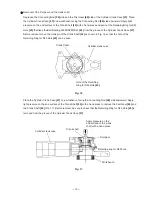

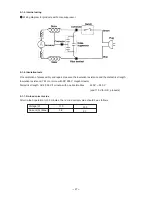

Mounting the first gear and the crank shaft

Mount the O-ring (S-40)

[44]

to the Cylinder Crank Case

[47]

. Press-fit the Ball Bearing 6203DDCMPS2L

[45]

and mount the Retaining Ring for D40 Hole

[43]

using a retaining ring puller. Press-fit the Crank Shaft

[42]

in

the Ball Bearing 6203DDCMPS2L

[45]

and mount the Oil Seal

[46]

. Put one Feather Key 4 x 4 x 10

[38]

in the

groove of the Crank Shaft

[42]

. Supporting the flat portion of the Crank Shaft

[42]

with a proper steel bar,

press-fit the First Gear

[60]

with a proper jig. Before press-fitting, check that the key groove of the Feather Key

4 x 4 x 10

[38]

is aligned with the key groove of the First Gear

[60]

(Fig. 19).

Fig. 19

Cylinder crank case

First gear

Feather key

Oil seal

O-ring

Ball bearing

Retaining ring for D40 hole

Steel bar

Suitable tool

Crank shaft

Содержание H45MRY

Страница 36: ......