English

6

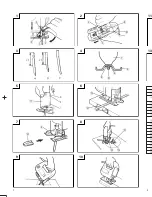

(1) Remove the 4mm screw, shown in

Fig. 4

, with the

accessory hexagonal bar wrench, and remove the

guide roller from the main body.

(2) To reassemble the main body and the base, insert

the base locker between the base and the 4mm screw,

as shown in

Fig. 4

, and securely clamp the 4mm

screw.

CHIP COVER POSITIONING

1. Chip cover

Use the chip cover to reduce flying of cut particles

and to easily operate the saw.

Slide the chip cover while lightly pressing its front

section.

The chip cover can be set at three positions as shown

in

Fig. 5

.

2. How to choose the position of the ship cover

Set the chip cover to the first step when attaching or

removing the blade.

Set the chip cover to the second step when cutting

wooden materials.

Set the chip cover to the second or third step when

cutting metal materials such as steel.

CAUTION

䡬

Keep always the chip cover in the low position when

operating the tool.

䡬

Wear protection glasses even if the chip cover is

used.

ADJUSTING THE BLADE OPERATING

SPEED .......................................... (FCJ55VA only)

NOTE

The blade operating speed cannot be adjusted for

FCJ55.

The blade operating speed can be adjusted within a

range of 0 to 3,000/min according to the degree that the

trigger switch is depressed. Select the speed appropriate

to the material being worked and/or the working

conditions.

To achieve continuous operation, pull the trigger switch

all the way back and depress the stopper. Then, turn the

speed adjustment knob to adjust the blade operating

speed as desired.

NOTE

The speed adjustment knob rotates approximately 3

turns. To turn the switch OFF, pull the trigger switch

again to disengage the stopper, and release the trigger

switch.

CUTTING

CAUTION

䡬

While sawing, the base must be firmly in contact with

the material surface, and the blade must be held at a

right angle. If the base becomes separated from the

material, it could cause the blade to break.

䡬

When cutting while holding the front surface, be

careful of the moving blade and hold the upper part

firmly.

1. Rectilinear cutting

(1) To ensure accurate rectilinear cutting, employ the

optional accessory guide as shown in

Fig. 6

.

(2) Use the splinter guard to reduce roughness of the

cutting surface of wooden materials. Attach the

splinter guard by inserting it from the front section of

the base until it clicks into place. (

Fig. 7

)

CAUTION

Set the base in the front position when using the

splinter guard.

2. Cutting a circle or a circular arc

To ensure efficient cutting, employ the optional

accessory guide and nail or wood screw as shown in

Fig. 8

.

When mounting the guide, loosen the base bottom

screw, and shift the base as far forward as it will go.

3. Sawing curved lines

When sawing a small circular arc, reduce the feeding

speed of the machine. If the machine is fed too fast, it

could cause the blade to break.

4. Cutting metallic materials

Always use an appropriate cutting agent (spindle oil,

soapy water, etc.). When a liquid cutting agent is not

available, apply grease to the back surface of the

material to be cut.

5. Pocket cutting

(1) In lumber

Aligning the blade direction with the grain of the

wood, cut step by step until a window hole is cut in

the center of the lumber. (

Fig. 9

)

(2) In other materials

When cutting a window hole in materials other than

lumber, initially bore a hole with a drill or similar tool

from which to start cutting.

6. Angular cutting

Set the chip cover to the first step. (

Fig. 5

)

To adjust the angle of inclination; loosen the base

bottom screw, shift the base position to the side

groove of the semicircular portion, align the scale on

the base semicircular portion (figures engraved on

the scale indicate the angle of inclination) with the

housing edge line, and thoroughly tighten the base

bottom screw. (

Fig. 10

and

11

)

CAUTION

Set the screw to the opposite side of the inclining

side when using the guide. (

Fig. 12

)

SELECTION OF BLADES

1. Accessory blades

To ensure maximum operating efficiency and results

it is very important to select the appropriate blade

best suited to the type and thickness of the material

to be cut. One type of blade is provided as standard

accessory. The blade number is engraved in the

vicinity of the mounting portion of each blade. Select

appropriate blades by referring to

Table 1

.

2. Acceptable commercial blades (Fig. 13)

This machine is designed to accept most blades

available on the open market. As illustrated in

Fig. 13

, blade dimension restrictions are as follows:

䡬

Thickness : L2 ..... Less than 1.6mm

䡬

Width

: L3 ..... 6.3mm

L4 ..... 8mm

L5 ..... 7mm

NOTE

When cutting thick materials, use HITACHI genuine blades

which have an inclination as shown in

Fig. 3-A

or

B

.