English

— 10 —

SPECIFICATIONS

Model

EC99S

Motor

Single-Phase, Induction Motor

Power Source

Single-Phase, 120 V AC 60 Hz

Running Horse Power

2 HP (1.45 KW)

Current

15 A

Tank Capacity

4 gal. (15.1 ltr)

Maximum Pressure

135 PSI (9.3 bar)

Free Air Delivery

at 40 PSI (2.8 bar)

3.64 CFM (103 ltr/min)

at 90 PSI (6.2 bar)

3.10 CFM (88 ltr/min)

at 100 PSI (6.9 bar)

3.05 CFM (86 ltr/min)

Lubrication

Oil

Weight

52.9 lbs (24 kg)

ACCESSORY

WARNING

: Accessory other than these shown

below can lead to malfunction and

resulting injuries.

STANDARD ACCESSORY

Dipstick ....................................................1

APPLICATIONS

Air source of the pneumatic nailer and stapler.

WARNING

: Never use compressor for applications

other than compressor for pneumatic

nailer and stapler.

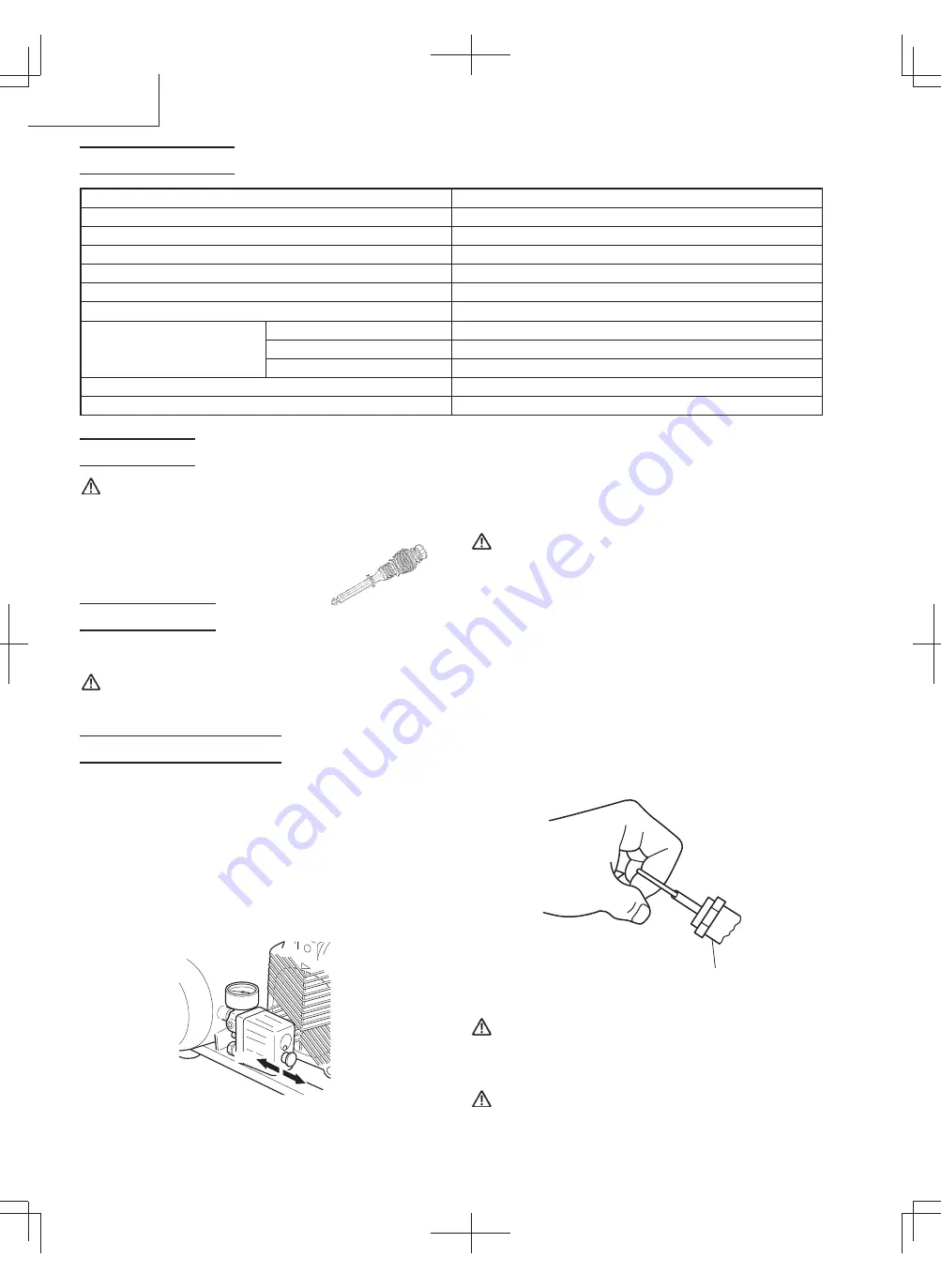

PRIOR TO OPERATION

1. Power

source

Ensure that the power source to be utilized conforms to

the power source requirements speci

fi

ed on the product

nameplate.

2. Power

switch

Ensure that the knob of the pressure switch is in the “OFF”

position (Fig. 2). If the plug is connected to a receptacle

while the knob is in the “ON” position, the compressor will

start operating immediately and can cause serious injury.

ON

OFF

Knob of the pressure switch

Fig. 2

3. Extension

cord

When the work area is far away from the power source,

use an extension cord of su

ffi

cient thickness and rated

capacity (refer page 7). The extension cord should be kept

as short as practicable.

WARNING

: Damaged cord must be replaced or

repaired.

4. Con

fi

rm the power receptacle

If the power receptacle only loosely accepts the plug, the

receptacle must be repaired. Contact the nearest electric

store for repair service.

If such a faulty receptacle is used, may cause overheating,

resulting in a serious hazard.

5. To check the safety valve.

Before starting compressor, pull the ring on the safety

valve to make sure that the safety valve operates smoothly.

(Fig. 3) Do not use compressor if the safety valve is stuck

or does not operate smoothly. Have defective safety valve

replaced by a Hitachi authorized service center.

Safety valve

Fig. 3

WARNING

: Drain tank to release air pressure

before pull the ring on the safety

valve.

WARNING

: Risk of bursting.

If the safety valve does not work

properly, over-pressurization may

occur, causing air tank rupture or an

explosion.

000Book̲EC99S̲lowes.indb 10

000Book̲EC99S̲lowes.indb 10

2018/03/09 10:49:29

2018/03/09 10:49:29