53

Confidential to Customer

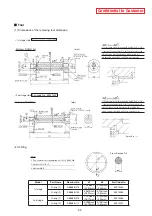

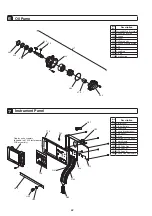

■

Tool

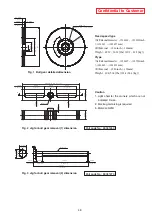

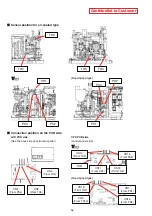

(1) Dimensions of the removing tool dimension

Part code No : 59031290

• 1st-stage side

Material : SCM415H

Drill through,

2 dia.

Drill through, 1.6 dia.

Drilled hole, 6 dia.,

98 deep

Drilled hole, 4 dia.,

90 deep

PS1/4, 15 deep

Pilot hole, 11.5 dia.,

18 deep

1. Thermal refining required (quenching at 850°C to 950°C(1562

℉

to 1742

℉

),

tempering at 550°C to 650°C(1022

℉

to 1202

℉

)) Hardness: HRC 32 to 40

2. M16 screws must be machined with a cutting tool.

3. Applicable model: DSP-45/55/75N 1st-stage side

(mm)

Part code No : 59031300

• 2nd-stage side

Material : SCM415H

Detail B (4 : 1)

1. Thermal refining required (quenching at 850°C to 950°C(1562

℉

to 1742

℉

),

tempering at 550°C to 650°C(1022

℉

to 1202

℉

)) Hardness: HRC 32 to 40

2. M12 screws must be machined with a cutting tool.

3. Applicable model: DSP-45/55/75N 2nd-stage side

Drill through,

2 dia.

PS1/4, 13 deep

Pilot hole, 11.5 dia., 15 deep

Drilled hole, 6 dia.,

110 deep

(mm)

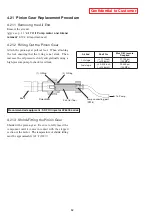

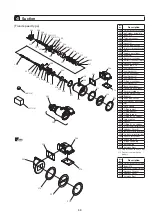

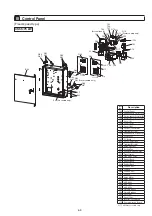

(2) O-Ring

Model

Part Name

Nominal No.

d1

d2

Part Code No.

1st-stage

O-ring (1)

AS568B-219

1.296inch

(32.92mm)

0.1390inch

(3.53mm)

59013040

O-ring (2)

AS568B-120

0.9870inch

(25.07mm)

0.1031inch

(2.62mm)

59013050

2nd-stage

O-ring (1)

AS568B-216

1.109inch

(28.17mm)

0.1390inch

(3.53mm)

59013060

O-ring (2)

AS568B-117

0.7988inch

(20.29mm)

0.1031inch

(2.62mm))

59013070

Notes

1. This item must be standardized by JIS or SEA AS568.

2. Hardness: Hs 70 ± 5

3. Material: NBR

Cross Section A-A