12

45

46

44

47

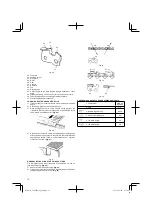

Fig. 39

35. Top plate

36. Working corner

37. Side plate

38. Gullet

39. Heel

40. Chassis

41. Rivet hole

42. Toe

43. Depth gauge

44. Correct angle on top plate (degree of angle depends on chain

type)

45. Slightly protruding “hook” or point (curve on non-chisel chain)

46. Top of depth gauge at correct height below top plate

47. Front of depth gauge rounded o

ff

.

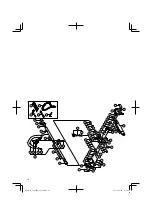

LOWERING DEPTH GAUGES WITH A FILE

1) If you sharpen your cutters with a

fi

le holder, check and lower the

depth.

2) Check depth gauges every third sharpening.

3) Place depth gauge tool on cutter. If depth gauge projects,

fi

le

it level with the top of the tool. Always

fi

le from the inside of the

chain toward an outside cutter. (

Fig. 40

)

Fig. 40

4) Round

o

ff

front corner to maintain original shape of depth gauge

after using depth gauge tool. Always follow the recommended

depth gauge setting found in the maintenance or operator

manual for your saw. (

Fig. 41

)

Fig. 41

GENERAL INSTRUCTIONS FOR FILING CUTTERS

File (48) cutter on one side of the chain from the inside out. File on

forward stroke only. (

Fig. 42

)

5) Keep all cutters the same length. (

Fig. 43

)

6) File enough to remove any damage to cutting edges (side plate

(49) and top plate (50)) of cutter. (

Fig. 44

)

48

48

48

Fig. 42

Fig. 43

49

50

Fig. 44

SHARPENING ANGLES FOR SHARPENING SAW CHAIN

1. Part Number

90SG-40

90PX-40

2. Pitch

3/8”

3. Depth Gauge Setting

0.025"

4. Side Plate Filing Angle

80°

5. Top Plate Angle

30°

6. File Guide Angle

90°

000Book̲CS27EPA(S)̲Eng.indb 12

000Book̲CS27EPA(S)̲Eng.indb 12

2014/06/04 15:14:27

2014/06/04 15:14:27