--- 6 ---

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Models CJ 65S3 and CJ 65V3 Jig Saws by all

of our customers, it is very important that at the time of sale the salesperson carefully ensures that the buyer

seriously recognizes the importance of the contents of the Handling Instructions, and fully understands the

meaning of the precautions listed on the Caution Plate attached to each tool.

7-1. Handling Instructions

Although every effort is made in each step of design, manufacture, and inspection to provide protection against

safety hazards, the dangers inherent in the use of any electric tool cannot be completely eliminated. Accordingly,

general precautions and suggestions for the use of electric power tools, and specific precautions and

suggestions for the use of the electric jig saw are listed in the Handling Instructions to enhance the safe, efficient

use of the tool by the customer. Salespersons must be thoroughly familiar with the contents of the Handling

Instructions to be able to offer appropriate guidance to the customer during sales promotion.

7-2. Cautions on the Name Plate

Each tool is provided with a Name Plate which lists the following basic safety precautions in the use of the tool.

7-3. Overload Durability Characteristics

The Models CJ 65S3 and CJ 65V3 have been designed specifically for home use, and their ability to withstand

overload is inferior to jig saws for professional use. Because oleo metal and polycarbonate resin are used for the

bearings and external components respectively, heat generation is high and heat radiation is inferior. Customers

should be cautioned that use of these models for professional level work could result in melting of the oleo metal

components and possible serious damage to other sections.

7-4. Use of Guide Roller

The new models are equipped with a guide roller which supports the load applied on the blade and bearing during

cutting operation, and helps prevent breakage of the blade and early wear of the bearing. When using the guide

roller, users should be instructed to pay particular attention to the following items described in the Instruction

Manual.

(1) Use a blade having a straight back portion (the back of the blade that contacts the guide roller) which is 50 mm

(2") or more in length (see Fig. a.). If a blade with an inclined back portion (see Fig. b.) is used, it will cause

excessive force on the plunger assembly, resulting in early malfunction of the bearing and the guide roller.

(2) The guide roller should be mounted so that its roller gently contacts the back of the blade. If the roller is

pressed too strongly against the blade during use, it will cause early malfunction of the bearing and other

parts, as described in paragraph (1) above.

Содержание CJ 65S3

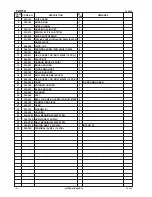

Страница 15: ... 12 9 5 Wiring Diagram 1 Model CJ 65S3 a Products with noise suppressor b Products without noise suppressor ...

Страница 22: ... 4 ITEM NO CODE NO DESCRIPTION REMARKS NO USED 10 05 CJ 65S3 Printed in Japan 051012N ...

Страница 26: ... 4 ITEM NO CODE NO DESCRIPTION REMARKS NO USED 10 05 CJ 65V3 Printed in Japan 051012N ...

Страница 27: ......