English

6

CUTTING

CAUTIONS

䡬

While sawing, the base must be firmly in contact

with the material surface, and the blade must be

held at a right angle.

If the base becomes separated from the material,

it could cause the blade to break.

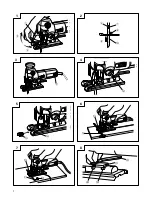

1. Rectilinear cutting

When cutting on a straight line, first draw a marking

gauge line and advance the saw along that line.

Using the auxiliary straight guide (sole separately)

will make it possible to cut accurately on a straight

line. Attach the guide by passing it through the

attachment hole on the base and tightening the M5

knob bolt. (

Fig. 6

)

2. Sawing curved lines

When sawing a small circular arc, reduce the feeding

speed of the machine. If the machine is fed too fast,

it could cause the blade to break.

3. Cutting a circle or a circular arc

In this case it will be helpful to use the auxiliary

circular guide and guide center (sold separately)

(

Fig. 7

).

Loosen the base handle located directly below the

housing by rotating it approximately 90 degrees.

Then move the base fully forward, rotate the base

handle approximately 90 degrees counterclockwise,

return the base to directly below the housing and

tighten (

Figs. 8, 9

).

Pass the circular guide through the attachment hole

on the base and tighten the M5 knob bolt.

4. Cutting metallic materials

Always use an appropriate cutting agent (spindle

oil, soapy water, etc.) When a liquid cutting agent

is not available, apply grease to the back surface

of the material to be cut.

5. Pocket cutting

(1) In lumber

Aligning the blade direction with the grain of the

wood, cut step by step until a window hole is cut

in the center of the lumber. (

Fig. 11

)

(2) In other materials

When cutting a window hole in materials other than

lumber, initially bore a hole with a drill or similar

tool from which to start cutting.

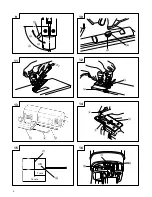

6. Angular cutting

To adjust the slant angle, loosen the base handle

located directly below the housing by rotating it

approximately 90 degrees and then move the groove

in the semi-circular part to the position indicated

by the mark on the gear cover.

Next, align the scale (from 0 degrees to 45 degrees

in 15-degree increments) of the semi-circular part

of the base with the [

] mark on the gear cover,

rotate the base handle approximately 90 degrees

counterclockwise, return to directly below the

housing and tighten (

Figs. 8, 9, 10, 12

).

CONCERNING CUTTING OF STAINLESS

STEEL PLATES

CAUTION

While sawing, the base must be firmly in contact with the

workpiece surface, and the blade must be held at a right

angle. If the base becomes separated from the material,

it could cause the blade to break.

When cutting stainless steel plates, adjust the unit as

described below:

1. Adjust the speed……

NOTE

Dial scale reading is for reference only. The higher

the speed is, the quicker the material is cut. But

the service life of the blade will be reduced in this

case. When the speed is too low, cutting will take

longer, although the service life will be prolonged.

Make adjustments as desired.

2. Set the orbital position to “0” ………

NOTE

䡬

When cutting use cutting fluid (oil base cutting

fluid) to prolong the blade’s service life.

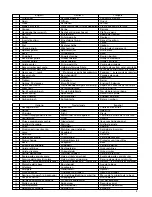

SELECTION OF BLADES

䡬

Accessory blades

To ensure maximum operating efficiency and results,

it is very important to select the appropriate blade

best suited to the type and thickness of the material

to be cut. Three types of blades are provided as

standard accessories. The blade number is engraved

in the vicinity of the mounting portion of each

blade. Select appropriate blades by referring to

Table 1

.

HOUSING THE SAW BLADES AND THE

HEXAGONAL BAR WRENCH

It is possible to house the auxiliary hexagonal bar wrench

and saw blades (2-3 blades) inside the base (see

Fig. 13

).

If saw blades get caught in the interior of the base, insert

the auxiliary wrench inside the groove on the back of the

base to remove the blades. (

Fig. 14

)

MAINTENANCE AND INSPECTION

1. Inspecting the blade

Continued use of a dull or damaged blade will

result in reduced cutting efficiency and may cause

overloading of the motor. Replace the blade with

a new one as soon as excessive abrasion is noted.

2. Inspecting the mounting screws:

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Inspecting the carbon brushes (Fig. 15)

The motor employs carbon brushes which are

consumable parts. When they become worn to or

near the “wear limit”, it could result in motor trouble.

When an auto-stop carbon brush is equipped, the

motor will stop automatically.

At that time, replace both carbon brushes with new

ones which have the same carbon brush Numbers

Blade

Thickness of material

Dial Scale

No. 96

0.5 ~ 1.5 mm

No. 95

1.5 ~ 2.5 mm

No. 97

1.5 ~ 2.5 mm

Middle groove position

between scales “2”

and “3”

Содержание CJ 110VA

Страница 3: ...1 3 1 4 5 6 7 8 1 2 3 4 8 9 7 A C D L K J I 2 B E F E G H E ...

Страница 4: ...2 9 10 11 12 13 14 15 L M N O J P T S F E U 7mm 14mm 46 R Q D 6 6 5 16 D ...

Страница 36: ...34 ...

Страница 37: ...35 ...