OPERATING PROCEDURES

GENERAL INFORMATION

Hiniker spreaders are capable of dispersing a

variety of dry materials for control of ice on road-

ways, walkways and parking lots.

Vehicle load carrying capacity limits the maxi-

mum load that can be safely transported, which

could be less than the volumetric capacity of the

spreader. Check the vehicle’s load rating certifi

-

cation sticker and DO NOT overload the vehicle

beyond its Gross Vehicle Weight Rating (GVWR)

or its Gross Axle Weight Rating (GAWR). Spread-

ers are recommended to be mounted on trucks

over 8,500 lb. GVWR.

Use the following tables to calculate vehicle pay-

load when material is loaded in the spreader.

VOLUMETRIC CAPACITY:

(Cubic Yards, Approx.)

LEVEL HEAPED

Standard 8’ Box

1.8

2.27

Standard 6 1/2’ Box

1.5

1.84

WEIGHT: (Pounds, Approx.)

8’ SS Standard Box

537

8’ Standard Box

602

6 1/2’ SS Standard Box

494

6 1/2’ Standard Box

550

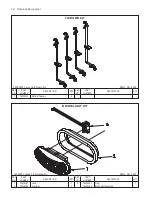

Short Spinner Kit

33

Long Spinner Kit

42

Hinged Hopper Grids, 8’ Box

55

Hinged Hopper Grids, 6 1/2’ Box

45

Adjustable Inverted “V”, 8’ Box

26

Adjustable Inverted “V”, 6 1/2’ Box

20

MATERIAL WEIGHTS:

(Pounds Per Cubic Yard, Approx)

Very Coarse Rock Salt

950

Coarse Rock Salt

1,215

Coarse Sand - Dry

2,565

Coarse Sand - Wet

3,240

Calculate total material weight by multiplying

pounds per cubic yard by cubic yards of mate-

rial.

Local, state and federal regulations may require

flashing lights, center high mounted stop light,

or other additional equipment for operation on

public roadways. It is the owners responsibil-

ity to know and follow laws as they apply in his

area.

Always examine the spreader for worn or dam-

aged components prior to operation. During

operation, listen for unusual noise from the

spreader that might indicate component failure.

Never run a machine in need of repair.

Start the spreader for a short period of time be-

fore loading material to test for proper function

of moving parts.

After loading, run the spreader in an isolated

area, clear of people, to become familiar with

the controls and to verify the correct spread pat-

tern. Adjust deflectors on the discharge chute to

achieve the desired spread.

WARNING: Stop the conveyor and set

the vehicle parking brake before leav-

ing the vehicle to make adjustments.

If loading the hopper the night before an im-

pending snowfall or ice storm, park the spreader

indoors, if possible, to help prevent freeze-up of

material before morning.

4 Operating Procedures

Содержание 615

Страница 2: ......

Страница 24: ...22 Parts Breakdown HOPPER ASSEMBLY DWG NO 6035 ...

Страница 28: ...26 Electrical Schematic ELECTRICAL SCHEMATIC DWG NO 6038 ...