Page 10

For technical questions, please call 1-888-866-5797.

Item 58260

SAFET

Y

O

PERA

TION

M

AINTENANCE

SETUP

Installing a Non-threaded Wheel

1. For a Grinding Wheel, it MUST be:

• rated to at least 8500 RPM.

• no larger than 5" (125mm) diameter.

• fitted with a 5/8

″

round arbor hole.

• from 0.245" - 0.300" thick.

• suitable for surface grinding, not edge grinding.

• dry and clean.

• proven undamaged by inspection.

For a Cut-Off Wheel, it MUST be:

• rated to at least 8500 RPM.

• no larger than 5

″

in diameter.

• fitted with a 5/8

″

round arbor hole.

• from 0.035" - 0.095" thick.

• suitable for edge grinding, not surface grinding

• dry and clean.

• proven undamaged by visual inspection.

WARNING! TO PREVENT SERIOUS

INJURY, When using a Cut-Off Wheel, a

wheel guard designed specifically for Cut-Off

Wheels (not included) must be installed for

adequate protection if the wheel fails.

WARNING! TO PREVENT SERIOUS INJURY,

Use only 4.5

″

grinding wheels with 4.5

″

guards.

Use only 5

″

grinding wheels with 5

″

guards.

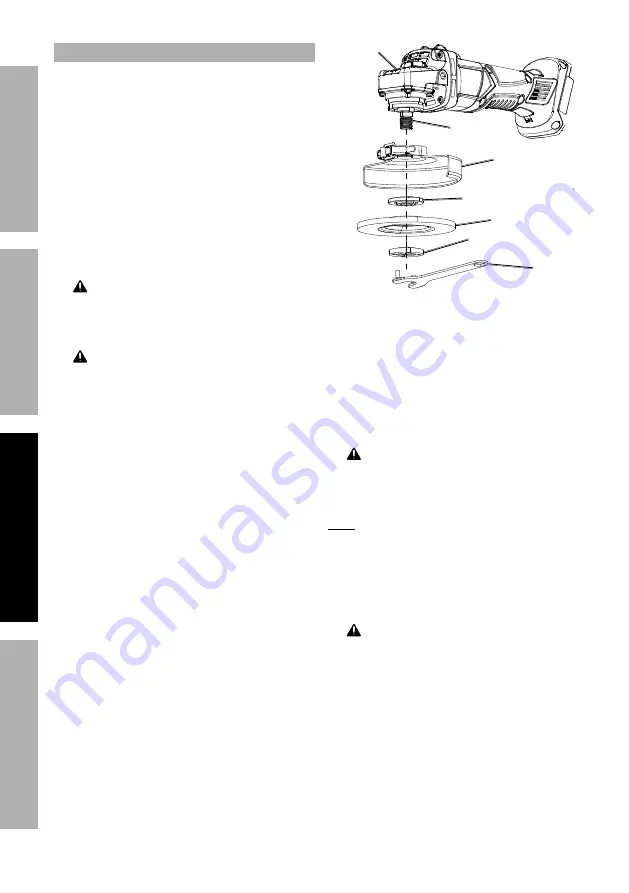

Wrench

Outer Flange

Grinding Wheel

Inner Flange

Wheel Guard

Spindle

Spindle

Lock

2. Press in and hold the Spindle Lock Button

to prevent the Spindle from turning.

3. Remove the Outer Flange.

Keep the Inner Flange in position on the Spindle.

4. Closely inspect the wheel before mounting.

5. For wheels with metal gaskets: Slip the

grinding wheel onto the Spindle with the gasket

first. The gasket should be centered on the

grinding wheel and the wheel and gasket

should rest flat against the Inner Flange.

6.

WARNING: To prevent serious

injury, gaskets must be used for all

grinding wheels they are provided with.

Gaskets help prevent grinding wheel damage

and wheel slippage, causes of wheel failure.

Note:

The Outer Flange has a step for improved

stability with thick accessories. Keep this step

on the inside for thick accessories. To allow

proper clamping for thin accessories, flip Outer

Flange so this step is on the outside.

7. Thread the Outer Flange onto the Spindle.

Wrench tighten only enough so that the wheel is

securely held on the spindle.

WARNING: To prevent serious injury,

do not overtighten flange. Overtightening can

damage the wheel, causing wheel failure.