MAINTENANCE

Important:

Use only a good grade hydraulic jack oil. Avoid mixing different types of fluid and

Never

use brake fluid, turbine

oil, transmission fluid, motor oil or glycerin. Improper fluid can cause failure of the jack and the potential for sudden and

immediate loss of load. We recommend Hein-Werner hydraulic jack oil HW93291.

Adding oil

1. With saddle fully lowered set jack in its upright, level position.

2. Remove the 4 bolts attaching the saddle assembly to the hydraulic unit. (see Figure 6)

3. Remove oil filler plug and release valve knob assembly to vent the reservoir.

4. Add hydraulic oil until it overflows. Reinstall the oil filler plug, release valve and saddle assembly.

Changing oil

For best performance, replace the hydraulic fluid completely at least once a year.

1. With saddle fully lowered, remove the 4 bolts attaching the saddle assembly to the hydraulic unit.

2. Remove the oil filler plug. Lay the jack on its side and drain the fluid into a suitable container.

3. Fill with oil until it overflows. Reinstall the oil filler plug and saddle assembly.

Note:

Dispose of hydraulic fluid in accordance with local regulations.

Lubrication

1. A periodic coating of light lubricating oil to all moving parts will help to prevent rust and assure that casters and pump

assemblies move freely.

2. When used on a daily basis, The air pump should be internally lubricated before each use. Use only good quality air tool

lubricant. If no inline oiler is used, pour a teaspoon of air tool oil into the inlet of the air supply inlet. Simply operate the

jack using the air feature in order to fully distribute the oil.

Figure 7. Valve Diagram

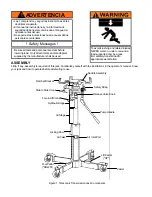

Figure 6

Bolt

Release Valve Knob