SAVE THESE INSTRUCTIONS

For your safety, read, understand, and follow the information provided with and on this jack. The owner and operator of this

equipment shall have an understanding of this jack and safe operating procedures before attempting to use. The owner and

operator shall be aware that use and repair of this product may require special skills and knowledge. Instructions and safety

information shall be conveyed in the operator's native language before use of this jack is authorized. If any doubt exists as

to the safe and proper use of this jack, remove from service immediately.

Inspect before each use.

Do not use if there are broken, bent, cracked, or damaged parts (including labels). Any jack that

appears damaged in any way, operates abnormally or is missing parts, shall be removed from service immediately. If the

jack has been or suspected to have been subjected to a shock load (a load dropped suddenly, unexpectedly upon it),

immediately discontinue to use until jack has been inspected by a Hein-Werner authorized service center. It is recom-

mended that an annual inspection be done by qualified personnel. Labels and Operator's Manual are available from

manufacturer.

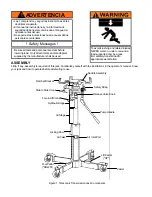

PRODUCT DESCRIPTION

Hein-Werner Telescopic Transmission Jack is designed to be used as an aid in the removal and installation of automotive

and light truck transmissions, transfer cases and transaxles.

It is intended for use under an overhead lift or in a garage pit.

Its air actuated features require an air source of 90-160 psi. To ensure dependable, trouble free operation an inline air dryer

and oiler is recommended.

SAFETY INSTRUCTIONS

BEFORE USE

1. Verify that the product and the application are compatible, if in doubt call Hein-Werner Technical Service (816) 891-6390.

2. Read the operator's manual completely and familiarize yourself thoroughly with the product, its components and recog-

nize the potential hazards associated with its use

before

using this product.

SPECIFICATIONS

Model

Capacity Min. Height Max. Height

Lifting Head Size

Forward Tilt Rearward Tilt

Sideways Tilt Chassis Size

(L x W)

HW93720

1/2 ton

34-1/2"

75"

11-1/2" x 11-1/2"

50

o

20

o

10

o

L & R

41" x 41"

• Read and understand all printed materials provided with and on this device before use.

• Do not exceed rated capacity.

• Ensure the center of gravity is centered on the saddle.

• Use only on hard, level, seamless surface.

• Use of this jack is limited to the removal, installation and transportation of transmissions, transfer cases and transaxles.

• Do not allow any part of your body under the load while jack is supporting a load.

• Use only the saddle assembly to lift. Never use any other part of the jack as a lifting surface.

• No alterations shall be made to this product.

• This is a lifting and lowering device only. Transfer load immediately to appropriate support device for service or repair.

• Only attachmens and/or adapters supplied by the manufacturer shall be used.

• Keep transmission at the lowest position when moving the transmission from one place to another.

• Adequately support the vehicle before starting repairs

• Use the straps to secure the transmission until ready to remove transmission from jack.

• When transferring a load to the lift, the air stage should be fully lowered or fully raised and pawl (locked). If a load is

transferred to the lift when the air cylinder is only partially raised, the lift may drop suddenly.

• Failure to heed these markings may result in personal injury and/or property damage.

!

WARNING