EN • 20

ENGLISH

FRANCAIS

NEDERLANDS

ESP

AÑOL

IT

ALIANO

DEUTSCH

664Y2800.B

Réf. 3:

The gas valve

offset setting is

a sealed factory

setting.

In principle,

it may not be

modified.

2

1

3

COMMISSIONING THE SYSTEM

Before pressurising the central heating circuit

(primary) you should first pressurise the domestic hot

water tank (secondary).

Both the domestic hot water tank and the central

heating circuit must be filled before using the boiler.

- Slowly fill the tank and drain it by opening a hot water tap. Drain

all the taps and check that there are no leaks in the domestic

hot water system.

- Fill the whole system up to a minimum pressure of 1 bar

(preferably 1.5 bar), using the boiler’s fill valve. Fill the system

slowly. Also check that the automatic air vent on the tank is

working. Check that there are no leaks in the central heating

system.

- Vent the shunt pump and unblock it if necessary.

- Open the gas tap, drain the pipe and check that there are no

leaks in the system.

- Place the condensing trap on the bottom face of the boiler and

check it is fill with water.

- Connect the plug to the wall socket and power on the appli-

ance. If needed, place the room thermostat to its highest

position. The boiler should start. Check the gas pressure and

allow the boiler to heat up for a few minutes. Set the boiler

to High Power mode and check the CO

2

level

(see the table

of Technical Characteristics)

. Then, set the boiler to Low Power

mode and check the CO

2

level again

(see the table of Technical

Characteristics)

.

- Set the central heating and hot water temperatures following

the values given in the Directions for Use.

- Drain the central heating system again and, if necessary, re-fill it.

- Make sure the central heating system is correctly balanced

and, if necessary, adjust the valves to prevent a greater or

lesser flow than planned to some circuits or radiators.

The condensate flow pipe diameter can not be decreased.

Moreover this pipe can never be blocked.

CHECKING THE SETTINGS

- Check that the parameters are set in accordance with the

user’s needs: see page 3, Directions for Use.

- Check the boiler settings: this task can only be carried out by an

ACV-trained installer or by the ACV maintenance department.

- Set the appliance to High Power mode by simultaneously pressing

the mode and Plus keys.

COMMISSIONING AND MAINTENANCE

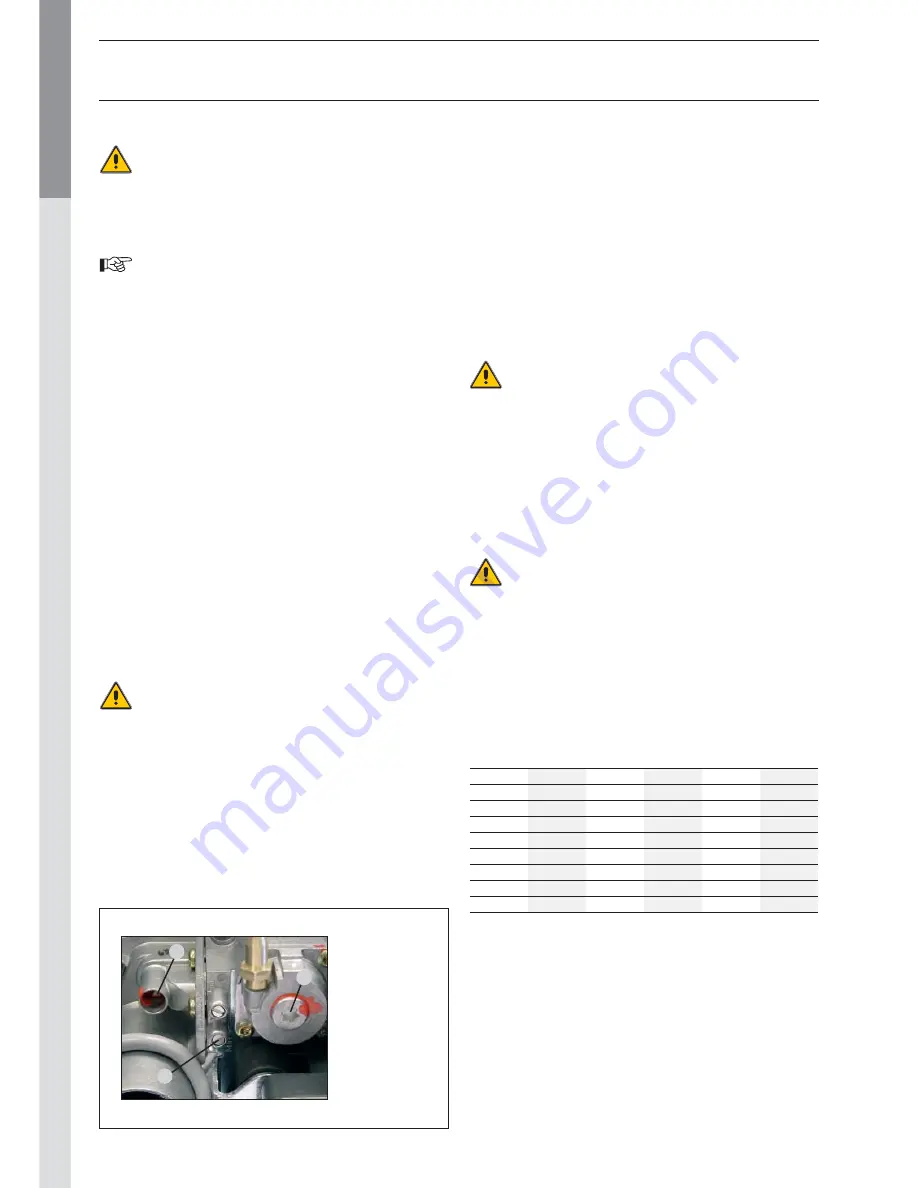

- Check the dynamic gas pressure at the gas valve

(see diagram

below, ref. 1)

. This must be at least 18 mbars. Wait a few min-

utes for the appliance to heat up to a minimum temperature of

60°C. Check the CO

2

setting using a measurement instrument.

Please see in the Technical Characteristics for optimum value.

To increase the CO

2

value, turn the venturi screw counterclockwise;

turn it clockwise to reduce the value

(see diagram below ref. 2)

.

Then put the appliance to High Power mode by simultaneously

pressing the mode and Plus keys. Wait a few minutes to stabilise.

Check

the

CO

2

value. It should be either equal to the full power

value or a maximum of 0.5% less than this value. If you record

a significant deviation,please contact the ACV maintenance

department.

INSPECTION AND MAINTENANCE

ACV recommends that you have your boilers inspected

and cleaned if need be at least once a year.

Plug out the appliance before undertaking any work, even if only

recording measurements and adjusting the settings.

- Check that the condenstrap is not fouled, fill it, if need be, and

check that there are no leaks.

- Check that the safety valves are operating correctly.

- Drain the whole system and if necessary re-fill the appliance to

pressure of 1.5 bar.

If you have to refill your circuit more than twice a year,

please contact your installer.

- Check the boiler charge in High Power mode. If there is a

big difference between this value and the original setting, the

deviation could mean a blockage in the air intake pipes or flue

gas extraction pipes, or that the exchanger has become fouled

with an accumulation of dirt.

TEMPERATURE SENSOR RESISTANCE TABLES

T° [°C]

R

Ω

T° [°C]

R

Ω

T° [°C]

R

Ω

- 20

98200

25

12000

70

2340

- 15

75900

30

9800

75

1940

- 10

58800

35

8050

80

1710

- 5

45900

40

6650

85

1470

0

36100

45

5520

90

1260

5

28600

50

4610

95

1100

10

22800

55

3860

100

950

15

18300

60

3250

20

14700

65

2750