26

Optional Controls

E. Copeland Demand Cooling for Discus L6 Models

Energy efficiency regulations drive continuous change in the availability of refrigerants

to the marketplace. With the introduction of R-22 as a replacement for R-502

compressors began to experience internal discharge temperatures that exceed the

safe operational limits for long term stability of refrigerant oil. In response to this

Demand Cooling was developed as a reliable method to keep discharge temperatures

reduced to a safe level without inhibiting the operating limits of the compressor. With

the phase out of R-22, the following refrigerants have become viable alternatives:

R-407A/C/F and R-448A/449-A. All of these refrigerants require special attention to

discharge temperature control. Also forthisreasonsuctiontoliquid heat exchangers are

not recommended unless they are necessary to prevent another potential problem.

The Copeland Demand Cooling System

Copeland's demand cooling system uses modern electronics to provide a

reliable, cost-effective solution to this problem. It is required for all single

stage required for all single stageR-22,R-407A/C/ForR-448A/449-A applications

with saturated suction temperatures below 0˚F.

The Demand Cooling module uses the signal of a discharge head temperature

sensor to monitor discharge gas temperature. If a critical temperature is reached,

the module energizes along life injection valve which meters a controlled amount of

saturated refrigerant into the compressor suction

cavity to cool the suction gas. Refer to Figure 13.

This process controls the discharge temperature to a safe level. If, for some

reason, the discharge temperature rises above a preset maximum level,

the Demand Cooling module will turn the compressor off (requiring a manual reset)

and actuate its alarm contact. To minimize the amount of refrigerant which must

be injected, the suction gas cooling process is performed after the gas has passed

around and through the motor.

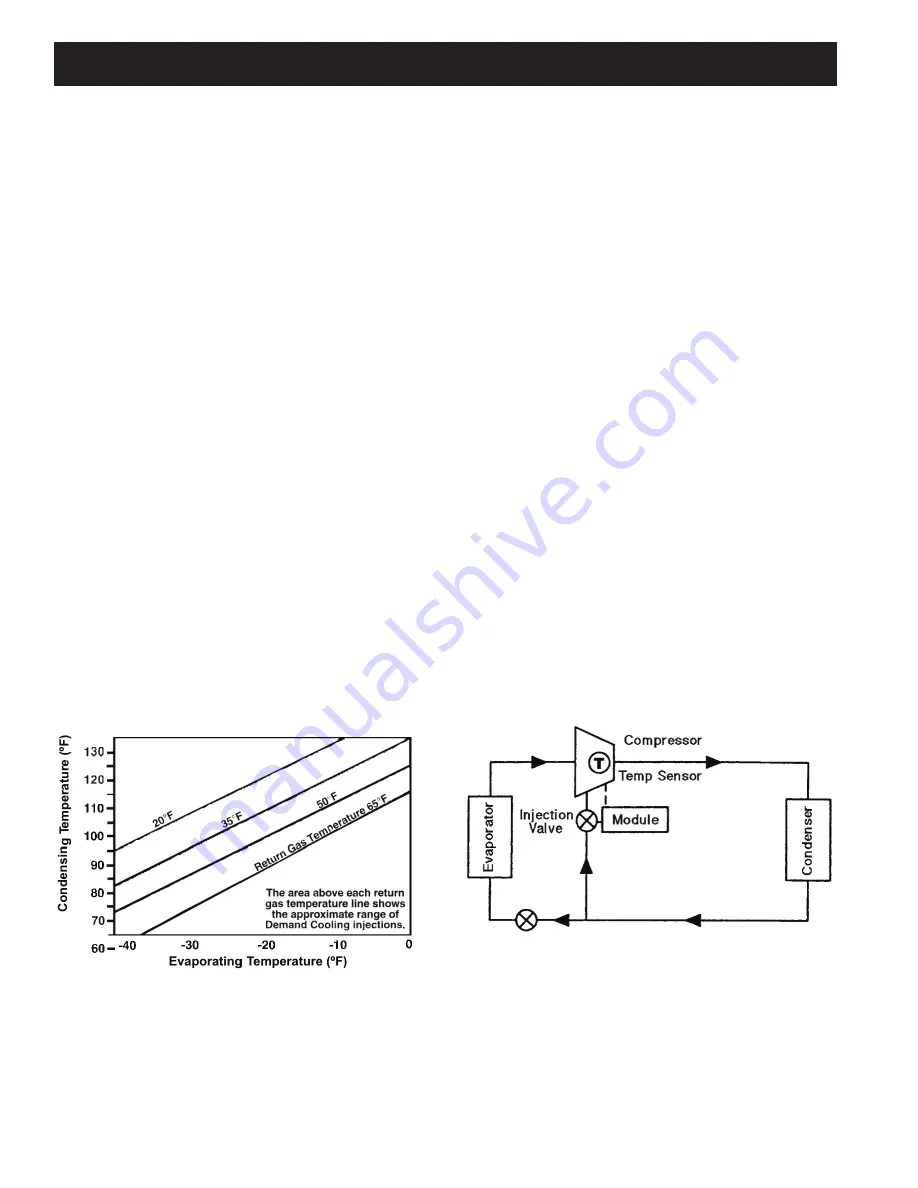

Operating Range

Demand Cooling is designed to protect the compressor from high discharge

temperatures over the evaporating and condensing temperature ranges shown in

Figure 12 at a maximum return gas temperature of 65˚F.

Figure 12. Demand Cooling Injection

Demand Cooling System Design

When Demand Cooling operates, it “diverts” refrigeration capacity in the form of

injected saturated refrigerant from the evaporator to the compressor. The effect of this

diversion on evaporator capacity is minimal because the diverted capacity is used to

cool the gas entering the compressor. As the gas is cooled, it naturally becomes more

dense, increasing the mass flow through the compressor, which partly compensates

for the capacity diverted from the evaporator.

1. Compressor Return Gas Temperature: Suction lines should be well

insulated to reduce suction line heat gain. Return gas superheat

should be as low as possible consistent with safe compressor

operation.

2. Condensing Temperatures: It is important when using R-22, R-407

A/C/F or R-448A/449A as a low temperature refrigerant that

condensing temperatures be minimized to reduce compression ratios

and compressor discharge temperature.

3. Suction Pressure: Evaporator design and system control settings

should provide the maximum suction pressure consistent with the

application in order to have as low a compression ratio as possible.

In most cases, with floating head systems where condensing temperatures

are low during most of the year, Demand Cooling will operate primarily as

a compressor protection control much as the oil failure control protects the

compressor during periods of low oil pressure. Demand Cooling will be

allowed to operate only during those periods when condensing temperatures

and return gas temperatures are high or in periods where a system failure

(such as an ice evaporator, an expansion valve which does not control superheat,

blocked condenser, or a failed condenser fan) raises condensing temperatures or

return gas temperatures to abnormally high levels or lowers suction pressure to

abnormally low levels.

Figure 13. Single Stage Internal Refrigerant Injection

Содержание Mohave

Страница 13: ...13 Piping The following are examples of proper piping layout for typical system configurations...

Страница 14: ...14 Piping...

Страница 38: ...38 Standard Independent Evaporator Power Supply with VFD Condenser Fans Wiring Diagram...

Страница 39: ...39 Standard Independent Evaporator Power Supply with VFD Condenser Fans Wiring Diagram...

Страница 45: ...45 Defrost Operation Black Piping Inactive Gray Piping Active Hot Gas Defrost Cycle Diagrams...

Страница 46: ...46 Defrost Operation Black Piping Inactive Gray Piping Active Hot Gas Defrost Cycle Diagrams...

Страница 75: ...75 Notes...