8

9. Sequence of Operation for Standard Unit

The BKP

TM

is controlled, on or off, by a dehumidistat which senses the relative humidity of the space.

The BKP

TM

units have a remote mounted dehumidistat and are designed to be used with a duct system

having a total external static of 0.5 in H

2

O or less.

On a call for dehumidification the contact in the dehumidistat is made sending control power through the

safety shutdown switches, through the lockout relay and to the blower relay. Control power is also sent

through a recycle time delay to the compressor contactor.

The safety shutdowns consist of a high and low refrigerant pressure cutout. If either of these cut-outs

open, the current path from the dehumidistat to the contactor is shifted through the coil of the lock-out

relay. The normally closed contact in the lockout relay opens and the normally open contact closes,

essentially shorting across the coil of the compressor contactor and providing full control voltage to the

lockout relay coil.

The contactor will remain off as long as the lockout relay receives voltage from the dehumidistat. Turning

the dehumidistat up and then back down, mechanically opens the contact in the dehumidistat, dropping

the power from the lockout relay.

After reset, voltage can now go through the normally closed contact of the lockout relay to the

compressor contactor and blower relay, provided the safety shutdown has cleared. Control power to the

contactor will be resumed through the off-cycle time delay when the machine has been off for the

selected number of minutes (factory set to 5 minutes for single phase units 3 minutes for 3 phase units).

A hot gas bypass valve is installed to prevent coil freeze-up. The hot gas bypass starts to open if the

suction pressure drops below 60 PSIG for any reason, and bypasses hot gas directly into the evaporator

to prevent the coil temperature from dropping below freezing.

The refrigerant system is a R-22 (Chlorodifluoromethane) system consisting of a compressor, condenser

coil, sight glass, filter dryer, Thermal expansion valve, and an evaporator with dehumidifier heat pipes.

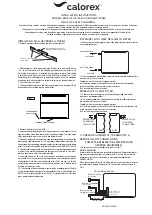

The coil section contains both the evaporator and condenser coils. The airflow enters through the precool

heat pipe then through the evaporator then the reheat heat pipe and the condenser.

9.1 Remote Condenser Units

The BKP-AC

TM

series operates similar to the standard unit except that it has a liquid receiver and

employs a separate outdoor condenser. Since the standard unit discharges air through the condenser

coil, the discharge air temperature will always be warmer than the inlet air and can reach temperatures

above 100

F. The BKP-AC

TM

unit, on the other hand has an outdoor condenser as well an indoor

condenser.

These units use a separate remote mounted thermostat along with the dehumidistat to control the BKP-

AC

TM

. The dehumidistat operates the unit on and off as described above. The thermostat controls a

reversing valve that diverts the refrigerant flow between the indoor and outdoor condensers. When the

temperature is below the set point, the valve sends the refrigerant through the indoor condenser. This

has the effect of warming the space temperature. When the temperature is above the set point the valve

sends the refrigerant through the outdoor condenser. The BKP-AC

TM

then acts as an air conditioner,

bringing the space temperature back down. The BKP-AC

TM

will switch back and forth between indoor and

outdoor condenser until the dehumidistat is satisfied.

The thermostat gets its control power from the red wire going to the dehumidistat. On a drop in

temperature, the thermostat contact sends control power directly to the reversing valve coil.

Содержание BKP 250

Страница 12: ...12 BKP 250 350 450 and AC Wiring Schematic ...

Страница 13: ...13 BKP 250 350 450 Wiring Diagram ...

Страница 14: ...14 BKP 250AC 350AC 450AC Wiring Diagram ...

Страница 15: ...15 BKP 250AC 350AC 450AC With Cooling Priority Wiring Schematic ...

Страница 16: ...16 BKP 250AC 350AC 450AC With Cooling Priority Wiring Diagram ...

Страница 17: ...17 BKP 250AC 350AC 450AC Remote Condenser Wiring Diagram ...