27

80+ HIGH ALTITUDE

INSTRUCTIONS

(TABLES 6 & 9)

INSTALLATION OF THIS FURNACE

AT ALTITUDES ABOVE 2000 FT (610

m) SHALL BE IN ACCORDANCE WITH

LOCAL CODES, OR IN THE ABSENCE

OF LOCAL CODES, THE NATIONAL

FUEL GAS CODE, ANSI Z223.1/NFPA

54 OR NATIONAL STANDARD OF

CANADA, NATURAL GAS AND

PROPANE INSTALLATION CODE,

CAN B149.1.

34" 80 Plus furnaces installed above

2,000 ft. require the furnace to be de-

rated 4% per thousand feet.

IMPORTANT:

Factory installed orifices

are calculated and sized based on a sea

level Natural Gas heating value of 1075

BTU per cubic ft.

NOTE:

Orifices are available through

your local distributor.

Reference Tables 6 and 9 for

appropriate orifice sizing.

The following are examples of orifice

sizing using the National Fuel Gas Code

Appendix F:

For a simplified estimation of orifice size

based on gas heating value and

elevation, Tables 6 and 9 may be used.

However, calculations are the best

method.

Example: 900 BTU/ft

3

Regional Natural

Gas Heating Value

I/H = Q

25000 / 900 = 27.78 ft

3

I = Sea Level input (per burner): 25000

H = Sea Level Heating Value: 900

Q = 27.78 ft

3

Natural Gas per hour.

From Table F.1 of

National Fuel Gas

Code Handbook, 2002

(3.5

ⴖ

w.c.

column).

Orifice required at Sea Level: #40

From Table F.4 of

National Fuel Gas

Code Handbook, 2002

Orifice required at 5000 ft. elevation (4%

de-rate per thousand ft): #42

Orifice required at 8000 ft. elevation (4%

de-rate per thousand ft.): #44

Example: 1050 BTU/ft3 Regional

Natural Gas Heating Value

I / H = Q

25000 / 1050 = 23.81ft

3

I = Sea Level input (per burner): 25000

H = Sea Level Heating Value: 1050

Q = 23.81 ft

3

Natural Gas per hour.

From Table F.1 of

Natural Fuel Gas

Code Handbook, 2002

(3.5

⬙

w.c.

column).

Orifice required at Sea Level: #43

From Table F.4 of

National Fuel Gas

Code Handbook, 2002

Orifice required at 5000 ft. elevation

(4% de-rate per thousand ft.): #45

Orifice required at 8000 ft elevation (4%

de-rate per thousand ft): #47

LP GAS (TABLE 7)

NOTE:

Keep any parts removed during

LP conversion procedure stored with

the product literature for future use.

LP Gas is a manufactured gas that has

consistent heating value across most

regions.

The NFGC guidelines are used with the

following exception:

The recommended LP Gas high

altitude orifice selections differ slightly

in that the NFGC LP orifice chart, as

they are not accurate for Rheem

products. The National Fuel Gas Code

LP orifices are based on an 11" of

water column pressure at the orifice,

which differs from products that use 10"

of water column at the orifice. This

difference requires a deviation from the

NFGC orifice size recommendations.

The Sea Level input should still be

reduced by 4% per thousand ft. and the

orifice size must be selected based on

the reduced input in Table 7.

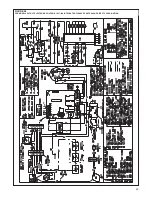

FIGURE 19

MANIFOLD PRESSURE-CHANGE LABEL

THE MANIFOLD PRESSURE OF THIS APPLIANCE HAS

BEEN FIELD ADJUSTED TO OBTAIN THE CORRECT

INPUT RATING FOR INSTALLATION AT ALTITUDES

BETWEEN 2,000 FEET AND 4,500 FEET ELEVATION.

LA PRESSION DU DISTRIBUTEUR D'ALIMENTATION

DE CET APPAREIL A ÉTÉ AJUSTÉ SUR LES LIEUX AFIN

D'OBTENIR LA BONNE PUISSANCE D'ENTRÉE POUR

UNE INSTALLATION ENTRE 2000 ET 4500 PIEDS

D'ALTITUDE.

92-24399-01-01

!

CAUTION

Natural Gas Orifice Drill Size (4% per 1000 ft. De-Rate)

IMPORTANT:

80+ Models only. Do not use this chart for any 90+ Models.

Burner Input (per burner) 25,000 BTU @ Sea Level

Sea level

2000 to

3000 to

4000 to

5000 to

6000 to

7000 to

8000 to

to 1999 ft

2999 ft

3999 ft

4999 ft

5999 ft

5999 ft

7999 ft

8999 ft

38

39

40

41

41

42

42

43

40

41

42

42

42

43

43

44

41

42

42

42

43

43

44

44

42

42

43

43

43

44

44

45

43

44

44

44

45

45

46

47

Annual Avg. Heat

Value (btu per ft

3

)

850

900

975

1075

1170

TABLE 6

TABLE 7

LP GAS

IMPORTANT: 80+ MODELS ONLY! DO NOT

USE THIS CHART WITH ANY 90+ MODELS.

Input (per

Orifice

Altitude

burner) 25000

Size

0 to 2000 ft.

25000

#54

2000

ⴕ

-3000

ⴕ

24000

#54

3000

ⴕ

-4000

ⴕ

23000

#54

4000

ⴕ

-5000

ⴕ

22000

#54

5000

ⴕ

-6000

ⴕ

21000

#54

6000

ⴕ

-7000

ⴕ

20000

#54

7000

ⴕ

-8000

ⴕ

19000

#55

8000

ⴕ

-9000

ⴕ

18000

#55

9000

ⴕ

-10000

ⴕ

17000

#55

Содержание GMDA

Страница 40: ...40 CM 0810...