Place the stove in the intended position and lift out the

hotplate, checking that the joint between the underside of

the hob and the top of the stove is intact. Any joints which

have opened shoud be made good with the fire cement

provided.

Replace the hotplate making sure that it seated evenly on

the soft rope and that it is approximately 0.1” (1.5mm)

higher than the enamelled top plate, with an equal space

all round. Fit the flue chamber which should have a rope

seal already installed. The flue chamber is screwed to the

stove making a good seal as any air leak at this point will

impede the working of the stove.

P/N - RS4M301136 A

Flue Chamber Box is located in Main Oven compartment

during shipment.

Remove all bubble wrap and protective film from inside of

oven doors prior to stove ignition.

Refer to Fig. 10 for definition of terms and installation

orientation of Flue Chamber.

a. Remove two screws (1/4” x 20) and fiber washers from

oven top cutout.

b. Prior to positoning Flue Chamber, ensure that chamber

damper is in its full open position to allow bar for

access to screw hole locations.

c. Position Flue Chamber on stove top ensuring that it is

nested as close as possible to the stove top, to allow

for a minimal gap - front and side.

d. Install fiber washers and 1/4” x 20 screws - ensuring

fasteners are tightly securing Flue Chamber.

e. Close Flue Chamber door.

Open the firebox and ashpit doors and check that the

reciprocating bottom grate bars are in position. Make sure

the three restriction plates are in place on the bottom grate

- one at the front and two at the rear. The riddling lever will

not operate with restriction plates in place, it is intended

for cleaning purposes only.

Be sure to read the sections on clearances, floor

protection and chimneys before actively starting the

installation.

A woodburning stove radiates heat in all directions. Heat

directed towards living areas in front of the stove is usually

very welcome. However, heat radiating in other directions

will not be as welcome if it results in overheating nearby

walls, ceilings or floors.

An important part of planning a safe installation is to be

sure that the combustible material located near your stove

does not overheat.

Clearance is the distance between your stove and

stovepipe and nearby walls, ceiling or floors.

If there is adequate clearance, then the nearby surfaces

will not overheat.

It is very important that you match the stove pipe you are

using to the clearance specified. Failure to do so will result

in an unsafe condition.

Unit must be placed on a continuous non-combustible pad

(floor tile with grouting or sheet metal pad) extending

21”(540mm) in front and 8” (203mm) to the side and back.

Air flowing between the stove pipe and nearby surfaces

carries away heat. Do not fill the empty space with any

insulating material.

A chimney approved to U L C 629 in Canada or UL 103

HT in the USA must be used to connect to the stove

pipe.

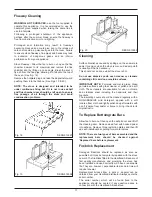

Handrail:

The handrail brackets are held on the front ends of the

stove top-plate casting. Remove the travel nuts and

replace with the handrail brackets ensuring the fibre

protecting washers are in position. Insert the handrail with

fitted endcaps into the brackets, positioning them

correctly, and tighten the locating bolts (See Fig. 1).

Do

not use handrail to move stove.

Endcaps, brackets and hardware, referenced in Fig. 1 are

located in the lower warming drawer during shipment.

Handrail is located on stovetop in a round tube during

shipment.

Do not hang combustible material on handrail during

stove operation.

Clearances must be maintained at all combustible

material. These include doors, trim, furniture, drapes,

newspapers and clothes. See local codes for a

description of combustible material.

Make sure that no floor or chimney supports will be cut

due to chimney installation.

Contact local building officials about restrictions and

installation inspection in your area.

Installation

Fig. 1

DESN 515137

Warning

The ashpit and firebox door must be closed

during normal use, except when lighting or

refuelling

6