Disinfection

Control Module and Cables

These may be cleaned with alcohol based disinfectant wipes.

Compatible agents (wipes and Solutions)

for disinfecting

Flexible Inspection Scope™

and Control Module:

Hydrogen peroxide

Isopropyl alcohol (IPA)

Sodium hypochlorite (Bleach)

Ortho-phenylphenol (OPP)

Quaternary ammonium

High-Level Disinfection (Flexible Inspection Scope™ Only)

Select only the disinfecting solutions listed in the compatible disinfecting methods.

Follow all recommendations regarding health hazards, dispensing, measuring, and

storage from the Mfr. of the cleaning and disinfecting agents.

Soak the Flexible Inspection Scope™ in the selected disinfecting solution per the

solution Mfr.’s IFU.

Rinse the Flexible Inspection Scope™ with critical (sterile) water, again, following

the instructions of the disinfecting solutions Mfr.

Reprocessing Chemical Compatibility Chart (PDF):

Click here.

Drying

Flexible Inspection Scope™ Only

Dry with a sterile, non-Linting wipe or sponge.

Ensure that the distal tip and proximal ends are dried.

Air drying could leave deposits on the optical surfaces, which could result in a

degraded image.

Maintenance, Inspection, and

Testing

Prior to use, carefully inspect the external surfaces of the Flexible Inspection

Scope™ and any accessories

to ensure they are smooth and free of any wear or

damage (i.e., protrusions or sharp edges).

Flexible Inspection Scope™ have no user:

o

serviceable parts.

o

maintenance beyond cleaning.

Refer all service or replacement needs to Healthmark Industries.

Light leaks may be common and possibly noticeable when inspecting the flexible

portion of the Flexible Inspection Scope™.

o

This does not influence its function, but it should be monitored for light

output.

o

Overly dark images on your monitor may be caused by damaged light

fibers and may require repair or replacement of the Flexible Inspection

Scope™.

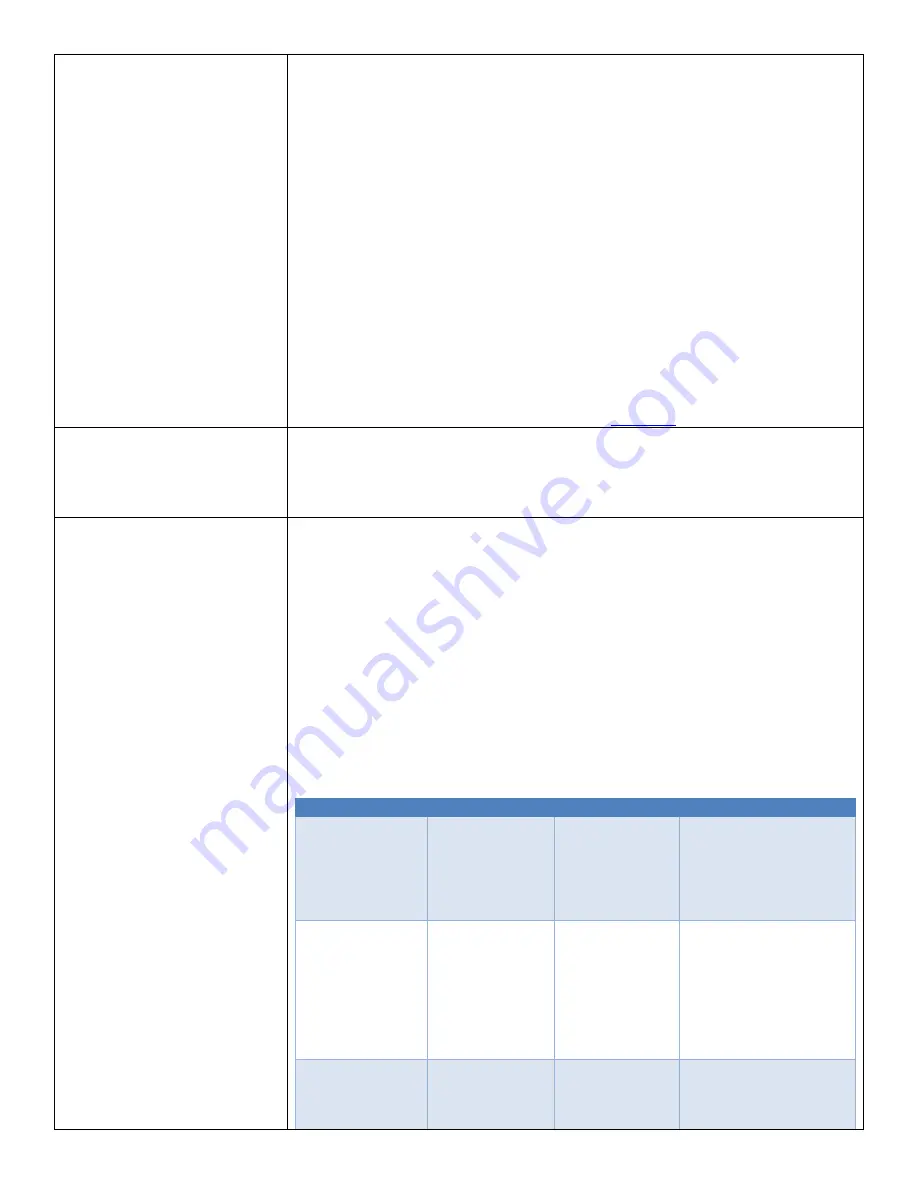

Troubleshooting and Servicing

Condition

Appearance

Cause

Correction

No image

Main image

Window is black.

The Inspection

Scope was not

connected to the

computer when

the software was

opened.

Unplug USB Connection

on Camera Cable and

plug in again.

No image

Main image

Window is black.

1. USB Video

Device not

selected, or

without the scope

connected.

2.Check HDMI

Monitor “Input”

Selection

If no image, to the

‘Settings’ Tab and select

USB Video Device.

No light

No light when

scope pointed at

surface.

No power to light

source or power

connections are

not secure.

1.Check the Camera

Cable connections and

make sure the computer is

powered on.

Document Version

2