13

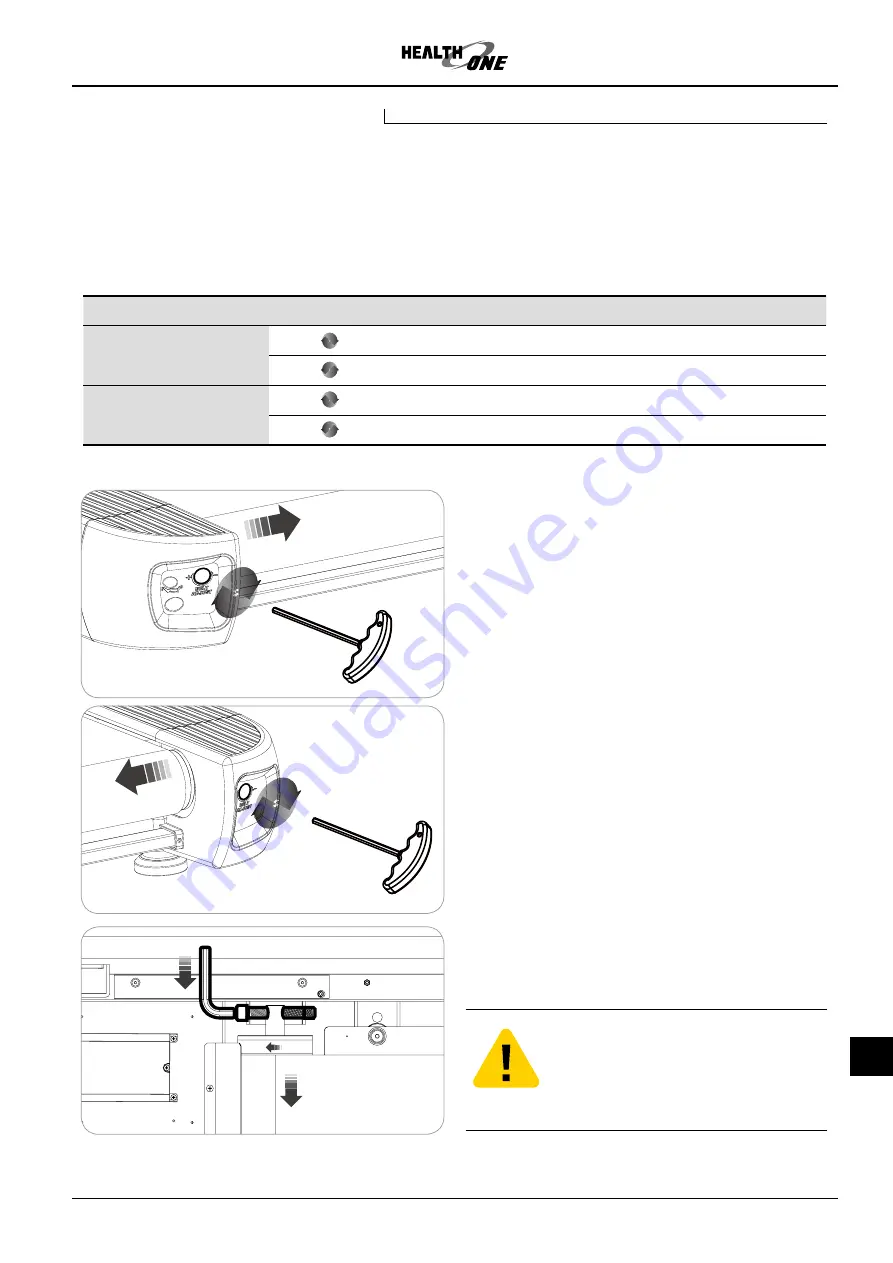

Belt tension and side-drift adjustment.

Belt tension must be adjusted whenever the machine was first installed or moved. Otherwise, it may cause slipping or damage

of belt or worn-down and breakage of other parts. Belt adjustment consists of belt tension adjustment and level adjustment.

Note : Turn the belt adjustment screw-heads in end-cover using 8 mm hexagon wrench to adjust the belt as shown in the above

Adjustment with T-Wrench and movement change of belt and roller

Adjustment of Tension

It is adjustment of distance between front and back rollers to obtain

optimal tension of the belt which is necessary to prevent slipping of

the belt during running..

1. Turn the power on.

2. Operate the machine at 4km/h.

3. Holding the handgrip, push the belt with foot to the opposite

direction of running. If the belt momentarily stops (slips), then

adjustment is necessary.

4. Adjust belt tension turning the adjustment screws left or right using

hexagon wrench. Repeat the process until no slippage occurs.

Adjustment of Side-drifting

After the adjustment of belt tension, adjust side-drifting as follows

1. Increase the belt speed to 10 km/h.

2. Adjust belt balance using 8mm hexagon wrench while visually

checking the belt for side-drifting.

3. If no sign of side-drifting shows after 5 minutes, then the balance

of belt has been achieved. If side-drifting occurs within 5 minutes,

repeat the process until balance is achieved.

4. If necessary, talce out the motor and adjust belt balmce by using

8mm L-wrench as shown in the picture

belt movement dir

ection

belt movement dir

ection

belt movement direction

A-6. INSTALLATION

A. GENERAL

Belt Section

Wrench movement

Roller shaft movement

Side-drifting

Left

(Fig. 1)

Clockwise

Left side backward

To the right

Counterclockwise

Left side forward

To the left

Right

(Fig. 2)

Clockwise

Right side backward

To the left

Counterclockwise

Right side forward

To the right

Do not turn the wrench without checking the change

in belt movement. Too much turning will push the belt

to one side and can damage it. It is recommended to

turn the wrench by 1/4 or 1/8 revolution at a time for

precise ad justment.

CAUTION