03/21

Model SP158.15

Page 4 of 8

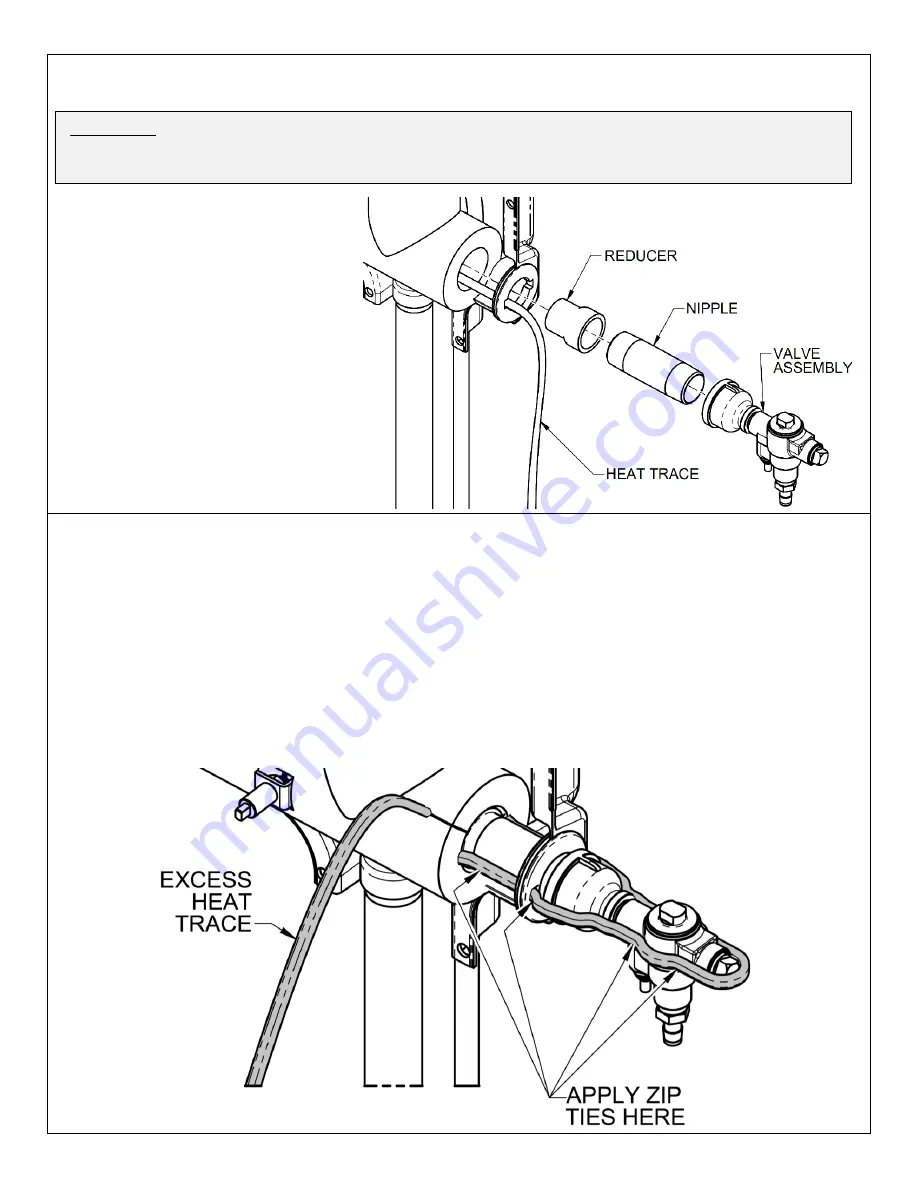

STEP 3: Plumbing

a) Run the heat trace out the grommet from Step 1, situating it within the nearest square cut in the grommet.

b) Connect and seal the galvanized

reducer, and then the galvanized

nipple, to the auxiliary outlet. The

nipple will run through the grommet,

with the heat trace alongside it.

c) Connect and seal the freeze valve

assembly to the end of the nipple.

Point the freeze valve drain fitting

downward.

d) Pressurize the plumbing and check

for leaks.

e) Make sure the heat trace is running

smooth and flat along the new

plumbing, but do NOT zip tie it into

place yet.

STEP 4: Heat Trace

a) Run the heat trace straight and level along the side of the plumbing and freeze valve. Wrap it around the

outlet plug of the freeze valve, then run it straight back along the opposite side.

b) Push the end of the heat trace through the open square cut in the grommet and feed the excess length

back within the jacket. The heat trace must run along the opposite side of the auxiliary outlet plumbing

until it rejoins the vertical shower piping. The excess length beyond this point should run out through the

insulation slit that the extra heat trace originally used. Store this excess length where the extra heat trace

was originally located.

c) Install the heat trace zip ties (found in a bundle of 6) approximately where shown. Use more than the 4

shown if needed.

The purpose of these zip ties is to ensure that the heat trace maintains solid

contact with the piping as continually as possible

– make sure the heat trace is ideally positioned

before tightening down the zip ties.

WARNING:

The heat trace must lay flush against the plumbing, contacting it wherever possible, in order

to transfer the necessary heat into the water. Failure to bring the heat trace into adequate contact with

the plumbing may cause local freezing within the plumbing, risking damage, leakage, and malfunction.