09/19 1200 Series Electric Water Coolers

Page 4 of 21

C. INSTALLATION OF HIGH-SIDE (LEFT) WATER COOLER

23. Remove the hanger bracket from the back of the cooler by removing (1) screw.

24. With the cooler laying on its back, remove the (4) screws holding the skirt to the bottom of the frame. Then remove the

skirt by sliding the skirt away from the cooler.

25. Mount the hanger bracket on the wall using (4)

1/4” structural screws, in accordance with the installation drawing.

a.

NOTE: The screws must engage into structural material such as concrete, metal backing, wood blocking, etc.

DO NOT use drywall anchors.

b.

NOTE: The hanger bracket has a notch indicating the centerline of the water cooler.

26. Using cutting pliers, cut the cable-tie holding the unconnected wires in the upper left side of the refrigerated cooler. These

wires will supply power, signal, and ground to the high side water cooler. Take care not to damage the wires when cutting

the tie.

27. Remove the protective plastic wrap from the feedthrough cover.

28. Feed the water tubing and wiring through the feedthrough cover. Install the feedthrough cover by sliding its upper right

tab behind the edge of the black cap of the right side water cooler (see installation drawing). Use a bubble level to ensure

the left edge of the feedthrough cover is vertical. Secure with a

1/4” or #10 screw.

a.

NOTE: Installing the screw into structural material is recommended. Toggle bolts or drywall anchors can be

used but they may make the unit more susceptible to damage from vandals.

29. Hang the cooler onto the hanger bracket.

a.

NOTE: The bracket must go thro

ugh the holes in the cooler frame that are shaped like a sideways letter “P”.

b.

NOTE: The bracket allows for some lateral adjustment of the cooler location. Slide the cooler laterally until it

touches the side of the feedthrough cover.

30. Secure both the lower right and lower left ends of the cooler to the wall using at least (2)

1/4” or 3/8” structural screws.

These screws should go through the holes which are approximately 5” from the bottom of the cooler. Washers may be

required.

a.

NOTE: The screws must engage into structural material such as concrete, metal backing, wood blocking, etc.

DO NOT use drywall anchors.

31. Route the drain hose from the left unit to the right unit. Attach to the open branch of the drain tailpiece using the supplied

hose clamp, ensuring that the drain hose slopes downward over its entire length.

32.

Attach the 3/8” water supply line to the 3/8” connector in the left side unit.

33. Connect the wire connector in the left unit.

34. Remove the green ground screw from its hole in the left unit and use it to secure the green ground wire to that same

location.

35. Snap wires into the plastic wire clip (near the ground screw) to keep them away from the sheet metal edges.

D. START-UP

36. Open the water supply valve and check the system for leaks.

37. Plug the power cord into the wall receptacle (which should presently be powered off at the breaker panel). Check that all

wiring is fully contained within the unit and that no wires are impeding fan blade movement.

38. Peel back the protective plastic from the bac

k flanges and top 1” of the skirt(s).

39. Taking care not to scratch the black plastic parts behind the bowl, reinstall the skirt(s). Finish removing the protective

plastic from the skirt(s).

40. Reconnect power at the breaker panel, then place a cup over the bubbler (to minimize splattering) and push the front

button to activate the bubbler flow. Keep the button depressed until all air is purged out of the water line.

a.

NOTE: If the unit has a filter, run the bubbler for 10 minutes in order to properly flush the filter.

41. If a bottle filler has been installed, place a cup under the nozzle of the bottle filler and run the water until the air has been

purged out of the water line.

42. If a high/low unit has been installed, place a cup over the bubbler of the second unit and push the front button to activate

the bubbler flow. Keep the button depressed until the air has been purged out of the water line.

43. The stainless steel panels can be cleaned with the provided cleaning wipe. Buff off excess with a clean cloth or paper

towel. Do not allow the cleaning fluid to touch the plastic parts or the bottle filler.

44. After allowing a few minutes for the water to cool down, enjoy a cold drink of water.

E. OPTIONAL PROGRAMMING INSTRUCTIONS (BOTTLE FILLER UNITS ONLY)

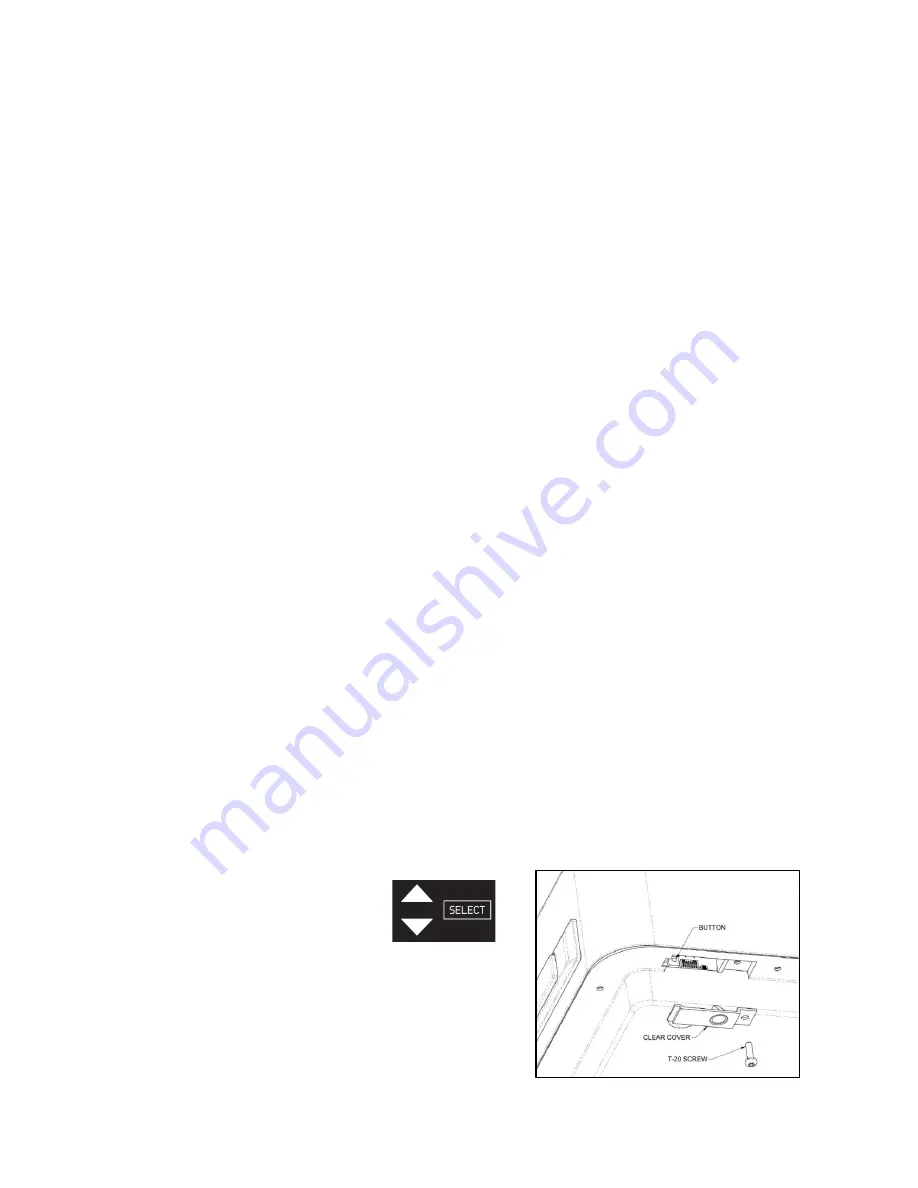

To enter programming mode, remove the clear cover underneath the bowl, and hold the button until the up/down arrow

keys and

“select” appear on the bottle filler display. Programming mode enters at the top-level menu. In general, the

up/down arrows and select keys work as follows;

Up/Down Arrows

– Cycle through the top-level menu items or

values in the programmable fields

Select

– enters programming of the associated top-level menu

item, or sets value and advances to next programmable field, or

programs value (indicated by value flashing) prior to returns to the

main menu

Programming the Haws 12 Electric Water Cooler through the bottle

willer user interface is intuitive. However, the following Electric

Water Cooler and Bottle Filler Programming Table can be used as

a guide while programming the unit, which are retained during

power outages.

Replace the clear plastic cover after programming the unit.

Figure 3: Programming Mode Button

viewed from underside of bowl